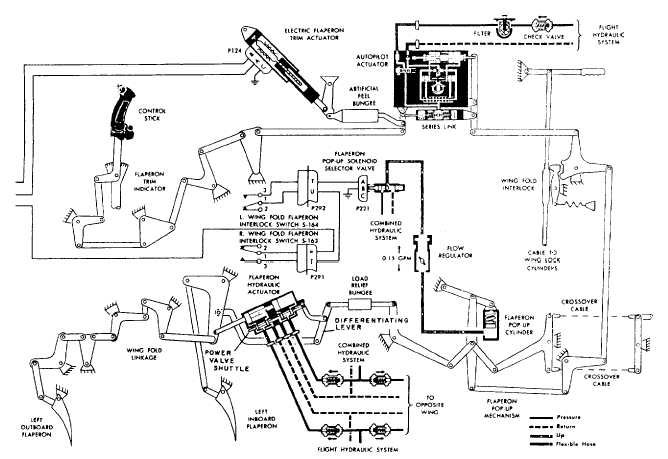

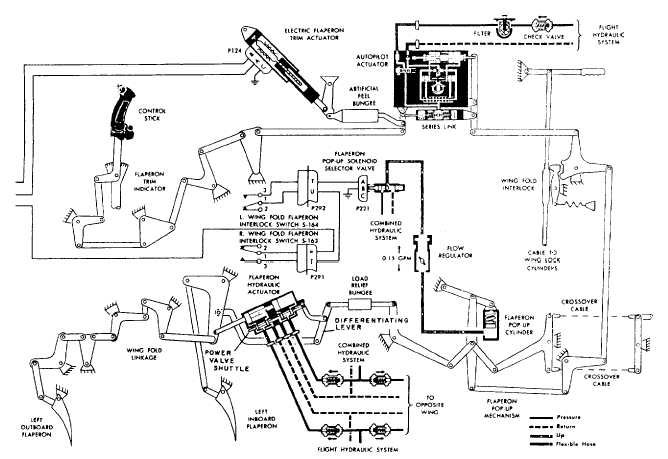

Figure 9-12 illustrates a representative flaperon

control system.

The flaperon autopilot actuator is

powered by the flight hydraulic system and transmits

mechanical movement to the flaperon power

actuators. The flaperon power actuators are tandem

type and powered by the combined and flight

hydraulic systems. They are capable of operating on

only one system if one system should fail.

The artificial-feel bungee provides an initial

control stick preload and increased force feel over the

full range of stick displacement. The electro-

mechanical actuator provides lateral trim, which

varies the neutral position of the artificial-feel

bungee. Trim is set by the switch on the control stick

grip. The pilot may read the mechanical flaperon trim

indicator on the control stick. See figure 9-10.

AUTOPILOT ACTUATOR.—The flaperon

autopilot actuator (figs. 9-12 and 9-13) contains an

electrohydraulic servo valve, actuator pistons,

solenoid valve, transducer, series link, and series-link

rod. It indirectly controls flaperon movement in

response to mechanical movements from the pilot. It

receives electrical inputs from the automatic flight

control system.

The actuator can operate in two

modes—manual or series.

In manual mode, the solenoid valve is de-energized

and no fluid is ported to any part of the actuator. The

actuator piston rod is free to idle. The series-link

cylinder acts as a rigid link that transfers input lever

motion to the output lever.

In series mode, the solenoid valve energizes and

ports pressure to the servo valve. Pressure from the

servo valve drives the actuator pistons together. This

pressure causes the pistons and the rod to act as one

piece. When the servo valve is at null, pressures in

the piston end chambers are equal. Electrical signals

Figure 9-12.—Flaperon control system.

9-14