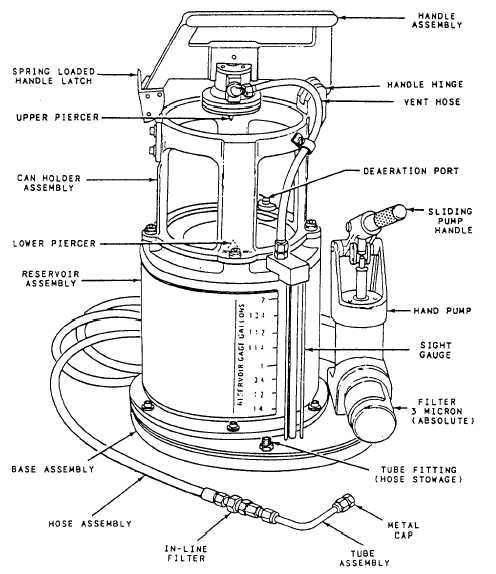

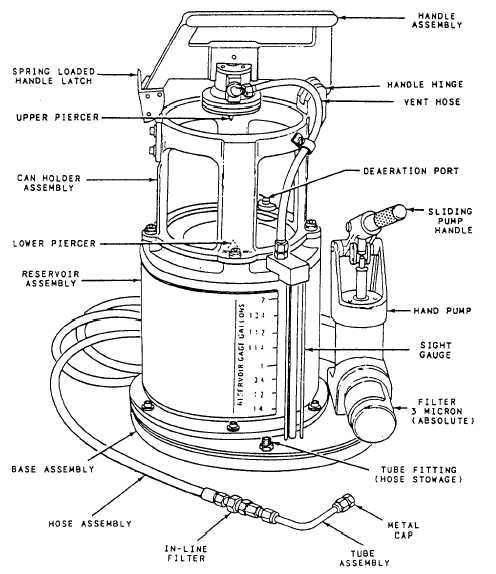

Figure 4-9.—Model HSU-1 fluid service unit.

The original fluid container serves as a reservoir

for the H-250-1 servicing unit. This container is not

opened until it is placed in the unit, and the handle

assembly pressed into a locked position. When the

handle is locked, the can is sealed into the unit by

cleanly piercing its top and bottom. This action

automaticallyy destroys the can’s potential for reuse.

The H-250-1 servicing unit is equipped with a top

piercing pin, which is drilled to provide the can with

atmospheric venting through a 5-micron filter. Also,

it has a check valve to minimize airborne particulate

and moisture contamination. The lower piercing pin

is drilled so the hydraulic fluid can reach the pump

through a passage in the base casting and a 3-micron

filter. The filter is a nonbypass type. When it

becomes loaded, the unit is inoperative. The filter

housing is designed so that the pump won’t operate if

a filter element has not been installed.

A pressure gauge, an air trap, and a manual air

bleed valve are attached directly to the pump

assembly base. The air trap automatically removes

any air present in the fluid at the pump chamber and

retains it in a separate trap. Air collected in the trap is

vented from the unit by manually operating a

spring-loaded, air bleed valve.

The H-250-1 servicing unit has an 8-foot service

hose that is equipped with a 3-micron, in-line filter

connected at the discharge end, which prevents

reverse flow contamination through the hose. There

are several types of disconnect fittings on the

reservoir service units of naval aircraft. There are no

mating fittings provided with the unit. Each activity

must procure and install the disconnect fitting

required for compatibility with the aircraft supported.

Both male and female fittings are procured so that

half can be installed on the hose end and half on the

bracket provided. The bracket-mounted fittings will

4-24