performance. With the exception of fluid cans or

drums installed in approved dispensing units, open

cans of hydraulic fluid are prohibited. Containers for

disposal of used fluid must be prominently marked

and identified. Empty fluid containers must be

destroyed or returned to supply as appropriate.

Do not reuse hydraulic fluid drained from

hydraulic equipment or components. Dispose of

drained fluid immediately so it won’t be accidentally

reused. In the event hydraulic fluid is spilled on other

parts of equipment on the aircraft, remove spilled

fluid using approved wiping materials and

dry-cleaning solvent P-D-680.

SPECIFIC SUPPORT EQUIPMENT

Several approved types of fluid-dispensing

equipment are available for use in servicing hydraulic

systems. The primary difference between the types of

equipment is their fluid-holding capacity. As you read

this section, refer to table 4-4, which lists the different

types of fluid-dispensing equipment. Do not use any

fluid servicing equipment other than that listed in the

table; they are not authorized unless specifically

approved for use by the aircraft controlling custodian,

cognizant engineering activity, NADEPs, or NAV-

AIRSYSCOM. All SE must be fitted with 3-micron

(absolute) filtration in the fluid discharge line. SE

construction must not expose fluid contents to

internally generated or external contamination.

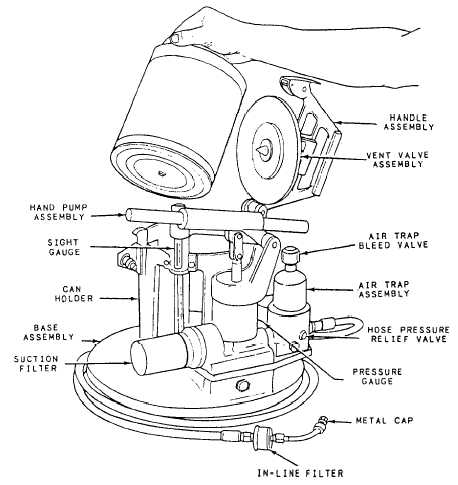

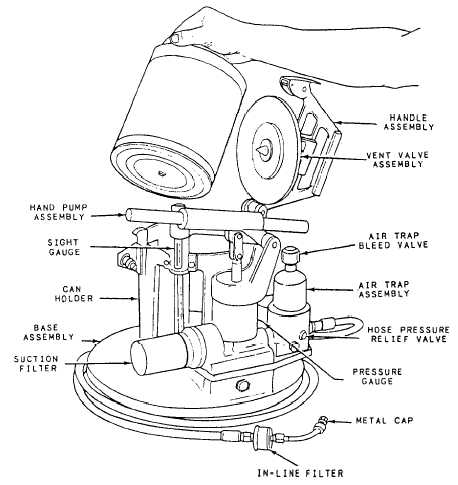

Model H-250-1 Hydraulic Servicing Unit

either

The Model H-250-1 hydraulic servicing unit is a

1-gallon servicing unit (fig. 4-8). It provides a way of

servicing systems by hand-pumping filtered fluid

directly from the original container without exposing

the fluid to open air or to other atmospheric

contamination.

The unit accepts the standard,

l-gallon container, which, when installed, serves as a

reservoir. The servicing unit has 3-micron (absolute)

filtration to prevent particulate contamination of a

system by new fluid that may not meet the prescribed

cleanliness prior to packaging. While contamination

in new fluid is rare, its occurrence has been reported.

Figure 4-8.—Insertion of can into Hydraulic Servicing Unit H-250-1.

4-23