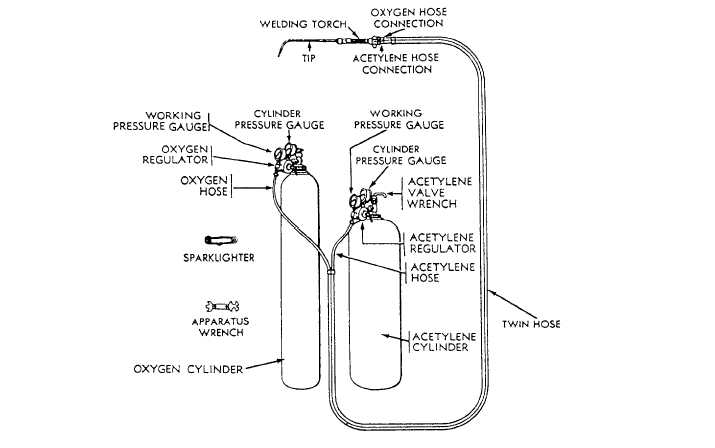

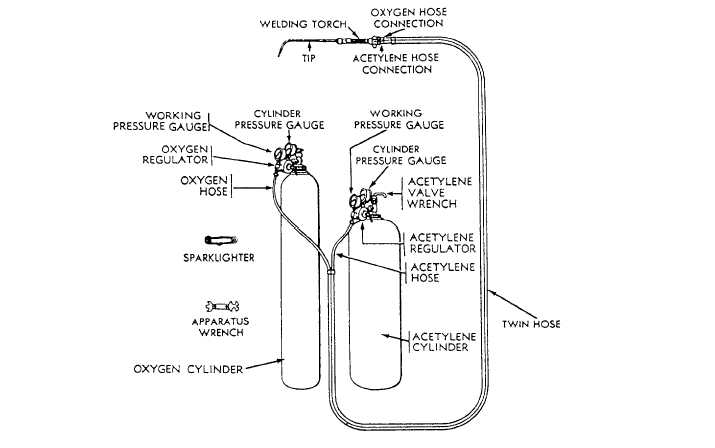

Figure 15-23.—Portable oxyacetylene welding and cutting equipment.

OXYACETYLENE WELDING

Oxyacetylene welding is a gas welding process. A

coalescence or bond is produced by heating with a gas

flame or flames obtained from the combustion of

acetylene with oxygen, with or without the application

of pressure, and with or without the use of filler metal.

A welding torch is used to mix the gases in the proper

proportions and to direct the flame against the parts to

be welded. The molten edges of the parts then literally

flow together and, after cooling, form one solid piece.

Usually, it is necessary to add extra material to the joint.

The correct material in rod form is dipped in and fuses

with the puddle of molten metal from the parent metal

parts.

Acetylene is widely used as the combustible gas

because of its high flame temperature when mixed with

oxygen. The temperature, which ranges from

approximately 5,700° to 6,300°F, is so far above the

melting point of all commercial metals that it provides

a means for the rapid, localized melting essential in

welding. The oxyacetylene flame is also used in cutting

ferrous metals. The oxyacetylene welding and cutting

methods are widely used by all types of maintenance

activities because the flame is easy to regulate, the gases

may be produced inexpensively, and the equipment can

be transported easily and safely.

Oxyacetylene Welding Equipment

The equipment used for oxyacetylene welding

consists of a source of oxygen and a source of acetylene

from a portable or stationary outfit. The portable outfit

consists of an oxygen cylinder and an acetylene cylinder

with attached valves, regulators, gauges, and hoses

(fig. 15-23). This equipment may be temporarily

secured on the floor or mounted on a two-wheel, welded,

steel truck equipped with a platform that will support

two large size cylinders. The cylinders are secured by

chains attached to the truck frame. A metal toolbox,

welded to the frame, provides storage for torches, tips,

gloves, fluxes, goggles, and necessary wrenches.

Stationary equipment is installed where welding

operations are conducted in a fixed location. The

acetylene and oxygen are piped to several welding

stations from a central supply. Master regulators are

used to control the flow of gas and maintain a constant

pressure at each station.

OXYGEN.—Oxygen is a colorless, tasteless, odor-

less gas that is slightly heavier than air. Oxygen is

15-17