nonflammable, but it will support combustion when

combined with other gases. This means that it aids in

burning, and this burning gives off considerable heat and

light. In its free state, oxygen is one of the most common

elements. The atmosphere is made up of approximately

21 parts of oxygen and 78 parts of nitrogen, with the

remainder being rare gases. It is the presence of oxygen

in the air that causes rusting of ferrous metals, the

discoloration of copper, and corrosion of aluminum.

This action is known as oxidation.

Oxygen is obtained commercially either by the

liquid air process or by the electrolytic process. In the

liquid air process, air is compressed and cooled to a point

where the gases become a liquid. As the temperature of

the liquid air is raised, nitrogen in a gaseous form is

given off first, since its boiling point is lower than that

of liquid oxygen. These gases, having been separated,

are further purified and compressed into cylinders for

use.

In the electrolytic process, water is broken down

into hydrogen and oxygen by the passage of an electric

current through it. The oxygen collects at the positive

terminal and the hydrogen at the negative terminal. Each

of the gases is then collected and compressed into

cylinders for use.

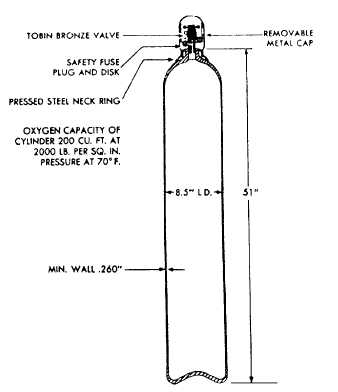

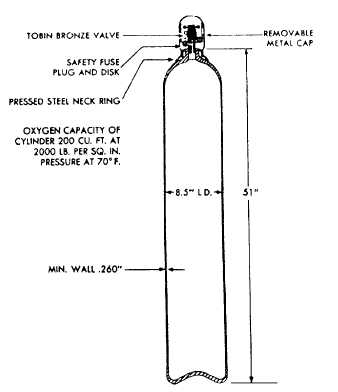

OXYGEN CYLINDERS.—A typical oxygen

cylinder (fig. 15-24) is made of steel and has a capacity

of 220 cubic feet at a pressure of 2,000 psi and a

temperature of 70°F. Each oxygen cylinder has a

high-pressure outlet valve located at the top of the

cylinder, a removable metal cap for the protection of the

outlet valve during shipment or storage, and a low

melting point safety fuse plug and disk. All oxygen

cylinders are painted green for identification. Technical

oxygen cylinders are solid green, while breathing

oxygen cylinders are green with a white band around the

top.

CAUTION

Oxygen should never be brought in contact

with oil or grease. In the presence of pure

oxygen, these substances become highly

combustible. Oxygen hose and valve fittings

should never be oiled or greased or handled

with oily or greasy hands. Even grease spots

on clothing may flare up or explode if struck

by a stream of oxygen.

PRESSURE REGULATORS.—The gases

compressed in oxygen and acetylene cylinders are at

pressures too high for oxyacetylene welding. Regulators

Figure 15-24.—Typical oxygen cylinder.

are necessary to reduce pressure and control the flow of

gases from the cylinders. Most regulators in use are

either the single-stage or the two-stage type. Single-

stage regulators reduce the pressure of the gas in one

step; two-stage regulators do the same job in two steps

or stages. Generally, less adjustment is necessary when

two-stage regulators are used.

Figure 15-25 shows a typical single-stage regulator.

The regulator mechanism consists of a nozzle through

which the high-pressure gases pass, a valve seat to close

off the nozzle, and balancing springs. These are all

enclosed in a suitable housing. Pressure gauges are

provided to indicate the pressure in the cylinder or

pipeline (inlet), as well as the working pressure (outlet).

The inlet pressure gauge, used to record cylinder

pressures, is a high-pressure gauge and is graduated

from 0 to 3,000 psi. The outlet pressure gauge, used to

record working pressures, is a low-pressure gauge and

is graduated from 0 to 500 psi.

In the oxygen regulator, the oxygen enters through

the high-pressure inlet connection and passes through a

glass wool filter that removes dust and dirt. Turn the

adjusting screw in, to the right, to allow the oxygen to

pass from the high-pressure chamber to the low-

pressure chamber of the regulator, through the regulator

outlet, and through the hose to the torch at the pressure

shown on the working pressure gauge. Changes in this

pressure may be made at will, simply by adjusting the

15-18