RECERTIFICATION OF WELDERS

Only currently certified aeronautical welders may

weld on aeronautical equipment. Initial certification is

attained by satisfactory completion of Navy training

course(s) N-701-0007 and/or N-701-0009, as

applicable. Certification can also be obtained by

documented satisfactory completion of equivalent

training in accordance with Aeronautical and Support

Equipment Welding Manual, NA 01-1A-34, and

satisfactory completion of recertification testing. If

proficiency is maintained, the recertification interval for

IMA-level aeronautical equipment welders is 3 years.

Maintaining proficiency requires documented

frequency of use, as specified in NA 01-1A-34. Failure

to maintain proficiency in any group(s) of metals will

terminate current certification in that/those group(s).

Recertification is normally accomplished by locally

producing acceptable test welds and submitting those

welds to the nearest authorized welding examination

and evaluation facility. Examination and evaluation

facilities must complete required testing of test weld

specimens and provide test results and recertification

documentation, as appropriate, to the affected welder’s

command within 30 days of the test weld(s) receipt.

Detailed procedures for obtaining test plates,

production and submission of test welds, and

documentation are contained in NA 01-1A-34.

TYCOMs/ACCs may extend current certification of

welders for a maximum of 90 days in cases where test

welds have been submitted but results and

recertification documentation have not been received

from the cognizant examination and evaluation facility.

Welders whose test specimens fail to meet minimum

requirements are allowed one retest. This retest will

require submission of a double set of test welds of the

failed group(s) of metal(s) to the same examination and

evaluation facility that failed the test welds first

submitted. Welding examination and evaluation

facilities will forward double sets of test plates to the

failed welder’s command concurrently with the

notification of failure. Retest test welds must be

completed and submitted within 30 days of receipt of

notification of failure of first test weld(s). Failure of any

retest test welds to meet minimum requirements will

require the welder to satisfactorily complete the Navy

training courses N-701-0008/N-701-0010, as appli-

cable, to recertify.

Aeronautical equipment welders may weld only on

equipment, components, and items manufactured from

the group of metals for which they are currently certified

and for which weld repairs are authorized by applicable

technical publications or directives. Groups of metals

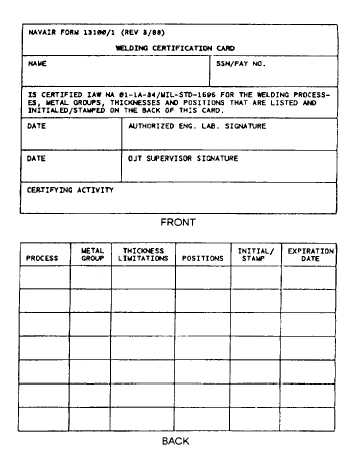

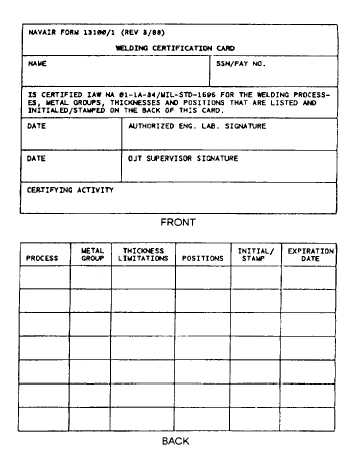

Figure 15-20.—Welding Certification NAVAIR 13100/1).

for which separate and distinct certification is required

are specified in NA 01-1A-34. Separate certification is

also required for oxyfuel brazing process.

NA 01-1A-34 contains additional information and

guidance relative to qualification, certification/recertifi-

cation, and employment of aeronautical equipment

welders. It is, however, a general series technical manual

intended to be used in conjunction with the OPNAV

4790.2E and with specific maintenance/repair/overhaul

manuals/engineering documents. In cases of conflict

between NA 01-1A-34 and the OPNAV 4790.2E

regarding certification/ recertification policy, the

OPNAV 4790.2E takes precedence.

QA/A is responsible for monitoring aeronautical

equipment welder certification/recertification. Refer to

the OPNAV 4790.2E for specifics.

A Welding Certificate (Operator’s Card), NAVAIR

13100/1, will be issued for each material category in

which the welder is qualified. The welding certificate

will be filled out, dated, and signed by an authorized

representative of an examination facility. Figure 15-20

provides a sample of the welding certificate. Figures

15-21 and 15-22 show a sample Welding Examination

Record (NAVAIR 13100/2) and instructions.

15-14