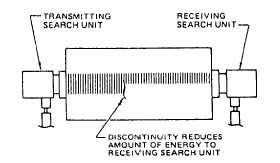

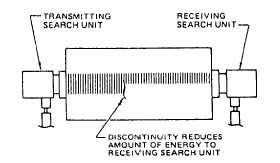

Figure 15-13.—Through-transmission inspection.

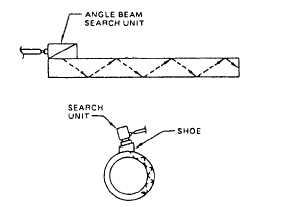

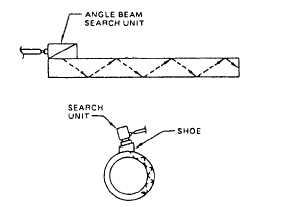

Figure 15-14.—Angle-beam inspection.

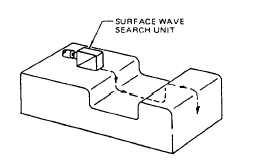

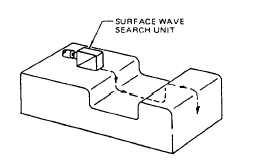

Figure 15-15.—Surface-wave inspection.

inspection of cylindrical components, examination of

skins for cracks, and inspection of welds. Figure 15-14

shows typical angle-beam inspections.

SURFACE WAVE.—The surface-wave method

projects a beam of vibrations that travel along the

surface and just below the surface of the material. When

surface waves are used to inspect painted surfaces, you

should exercise caution during set up and interpretation

due to the possibility of surface reflection from scratches

and breaks in the painted surface. Surface-wave

inspections can be used in many field NDI applications

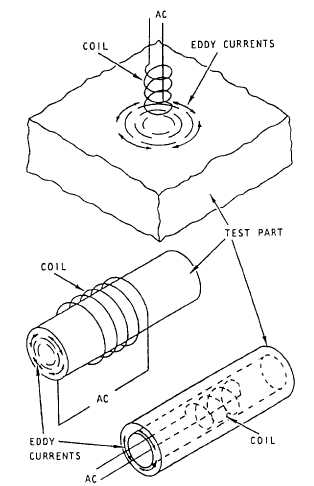

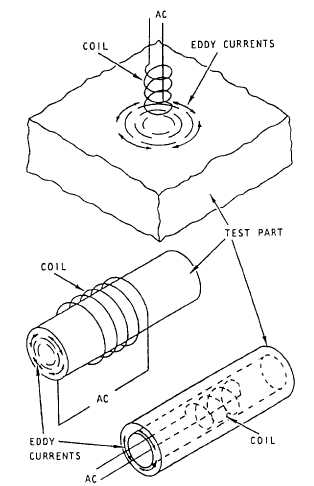

Figure 15-16.—Generation of eddy currents in various part con-

figurations.

involving surface cracks or slightly subsurface

discontinuities. On smooth surfaces, sound energy can

travel long distances with little energy loss. Surface

waves travel around curved corners, and they reflect at

sharp edges. Rough surfaces or liquid on the surface

attenuate surface waves so the area in front of the search

unit must be kept clear of couplant. Figure 15-15 shows

a typical surface-wave inspection.

Eddy Current Inspection

Eddy currents are electrical currents induced in a

conductor of electricity by reaction with a magnetic

field. The eddy currents are circular in nature, and their

paths are oriented perpendicular to the direction of the

applied magnetic field. In general, during eddy current

testing, the varying magnetic field(s) is/are generated by

an alternating electrical current (ac) flowing through a

coil of wire positioned immediately adjacent to the

conductor, around the conductor, or within the

conductor. Figure 15-16 shows eddy currents flowing in

various configurations.

15-11