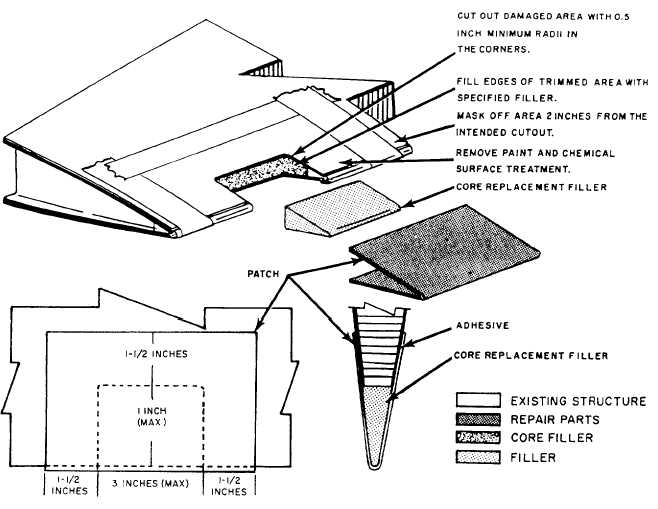

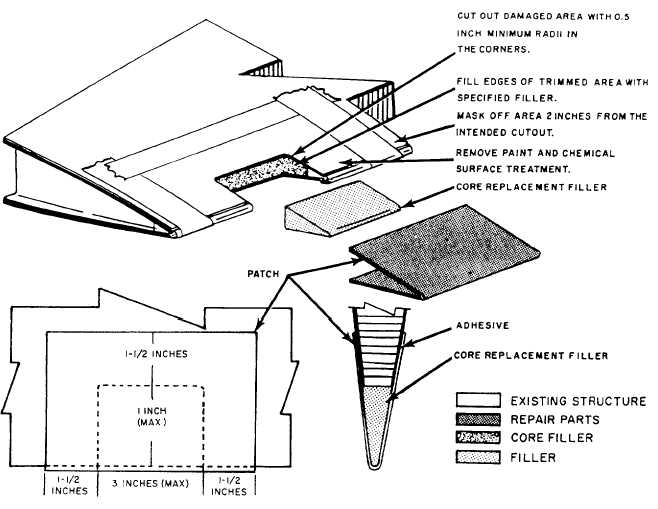

Trailing edge repairs to all-metal construction

assemblies and/or control surfaces are performed by

using basically the same procedures outlined in the

chapter titled “Aircraft Metallic Repair.” A typical

trailing edge repair to a sandwich construction

assembly is shown in figure 14-20.

You may use the lap or flush patch, depending on

the size of the damage, the type of aircraft, and the

assembly or control surface to be repaired. Normally,

the flush patch is used on control surfaces to ensure

aerodynamic smoothness.

TYPES OF ADVANCED COMPOSITE

MATERIALS

The reduced availability of natural resources, the

increasing costs of production, and the apparent limit

to our ability to fabricate high strength-to-weight

metallic components necessitated the development of

new materials to meet the demands of aerospace

technology. In the following text, you will be intro-

duced to the materials that provide high-performance

capability now, with great expectations for the future.

These materials are called advanced composite

materials and will be used to replace some of the

metals currently used in aircraft construction.

Advanced composites are materials consisting of

a combination of high-strength stiff fibers embedded

in a common matrix (binder) material, generally

laminated with plies arranged in various directions to

give the structure strength and stiffness.

The much stiffer fibers of boron, graphite, and

Kevlar® have given composite materials structural

properties superior in strength to the metal alloys that

they have replaced. Specific applications of advanced

composite materials and approximate percentages of

total aircraft structures for some of our modern-day

aircraft are shown in table 14-1.

Figure 14-20.—Trailing edge repair (sandwich construction).

14-18