A variety of clamping devices are used

in connecting aircraft environmental control

system ducting sections to each other or

to various components. Whenever lines, com-

ponents, or ducting are disconnected or re-

moved for any reason, install plugs, caps,

or coverings on the openings to prevent

the entry of foreign materials. Tag the various

parts to ensure correct reinstallation. Care

should be exercised during handling and installa-

tion to ensure that flanges are not scratched,

distorted, or deformed. Flange surfaces should

be free of dirt, grease, and corrosion. The

protective flange caps should be left on the

ducting until the installation progresses to the

point where removal is necessary to continue with

the installation.

In most cases it is mandatory to discard and

replace seals and gaskets. Ensure that seals and

gaskets are properly seated and that mating and

alignment of flanges are fitted so that excessive

torque is not required to close the joint and

impose structural loads on the clamping device.

Adjacent support clamps and brackets should

remain loose until installation of the coupling has

been completed.

Marman type clamps commonly used in

ducting systems should be tightened to the torque

value indicated on the coupling. Tighten all

couplings in the manner and to the torque value as

specified on the clamp or in the applicable MIM.

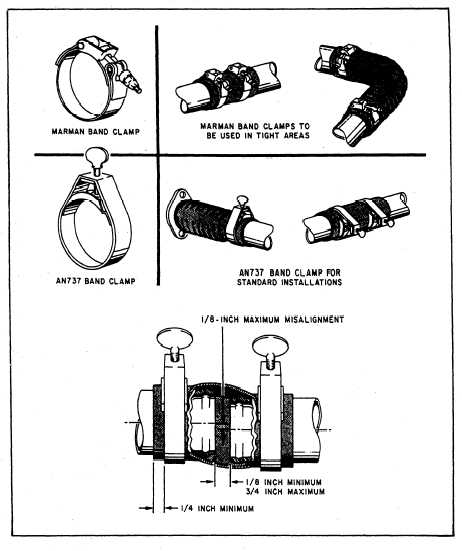

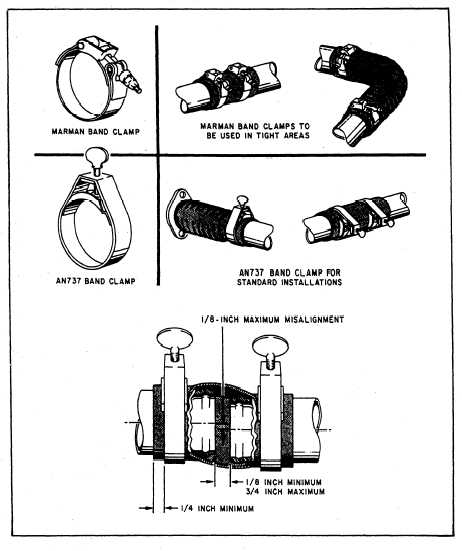

Some of the most commonly used plain band

couplings (flexible line connectors) are illustrated

in figure 3-7. When installing a hose between two

Figure 3-7.—Flexible line connectors.

3-9