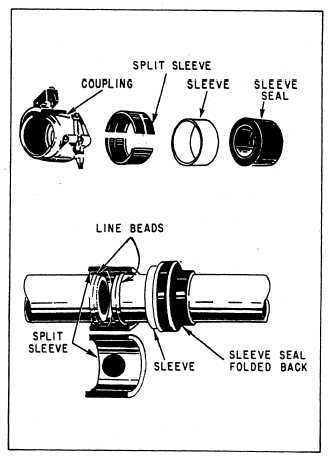

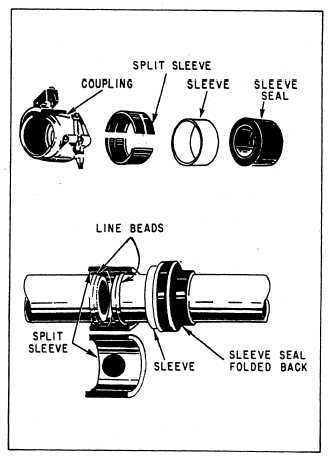

duct sections, as illustrated in figure 3-7, the gap

between the duct ends should be 1/8 inch

minimum to 3/4 inch maximum. When install-

ing the clamps on the connection, the clamp

should be 1/4 inch minimum from the end of the

connector. Misalignment between the ducting

ends should not exceed 1/8 inch maximum.

When installing flexible line connectors, such

as the one illustrated in figure 3-8, follow the steps

listed below to assure proper installation and

security:

1.

2.

3.

4.

5.

Fold back half of the sleeve seal and slip

it onto the sleeve.

Slide the sleeve (with the sleeve seal

partially installed) onto the line.

Position the split sleeves over the line

beads.

Slide the sleeve over the split sleeves and

fold over the sleeve seal so that it covers the

entire sleeve.

Install the coupling over the sleeve seal and

torque to correct value.

NOTE: Torque values for the various sizes

and types of couplings maybe found by referring

to the applicable MIM. Some couplings will have

the correct torque value marked on the outside

of the band.

When installing rigid line couplings, follow

the steps listed below and illustrated in fig-

ure 3-9:

1. Slip the V-band coupling over the flanged

tube.

2. Place a gasket into one flange. One quick

rotary motion assures positive seating of the

gasket.

3. Hold the gasket in place with one hand

while the mating flanged tube is assembled into

the gasket with a series of vertical and horizontal

motions to assure the seating of the mating flange

to the gasket.

NOTE: View B of figure 3-9 illustrates the

proper fitting and connecting of a rigid line

Figure 3-8.—Installation of flexible line connectors.

coupling, using a metal gasket between the

ducting flanges.

4. While holding the joint firmly with one

hand, install the V-band coupling over the two

flanges.

5. Press the coupling tightly around the

flanges with one hand while engaging the latch.

6. Tighten the coupling firmly with a ratchet

wrench. Tap the outer periphery of the coupling

with a plastic mallet to assure proper alignment

of the flanges in the coupling. This will seat the

sealing edges of the flanges in the gasket. Tighten

again, making sure the recommended torque is

not exceeded.

7. Check the torque of the coupling with a

torque wrench and tighten until the specified

torque is obtained.

3-10