environment destroying the anodic area. Note that the

surface of a metal may contain anodic and cathodic

areas because impurities or alloying constituents may

have different potentials than the base metal.

Electrochemical attack is evident in several forms.

The form you find depends upon the metal involved,

its size and shape, its specific functions, atmospheric

conditions, and type of corrosion-producing agent

(electrolyte) present.

There are many factors that affect the type, speed,

cause, and the seriousness of metal corrosion. Some of

these factors you can control; others you cannot.

Preventive maintenance factors, such as inspections,

cleaning, painting, and preservation, are within the

control of the operating squadron. They offer positive

means of preventing corrosion.

The electrochemical reaction, which causes metal

to corrode, is more dangerous under wet, humid

conditions than under dry conditions. The salt in

seawater and the salt in the air are the largest single

cause of aircraft corrosion. Hot climates speed the

corrosion process because the electrochemical

reaction develops fastest in a warm solution. The warm

moisture in the air is usually enough to start corrosion

of the metals if they are uncoated. As expected, hot,

dry climates usually provide relief from constant

corrosion problems. Extremely cold climates will

produce corrosion problems when a salt-laden

atmosphere is present. Melting snow or ice provides

the necessary water to begin the electrochemical

reaction.

Thick structural sections are subject to corrosive

attack because of possible variations in their

composition, particularly if they were heat-treated

during fabrication. Similarly, when large sections are

machined or cut out after heat treatment, thinner

sections have different physical characteristics than

the thicker areas. Usually a difference in physical

characteristics provides enough difference in

electrical potential to make the piece highly

susceptible to corrosion. Another factor relating to the

size of materials is the relationship between dissimilar

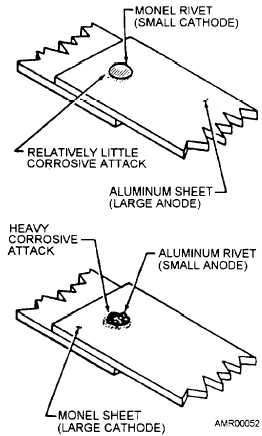

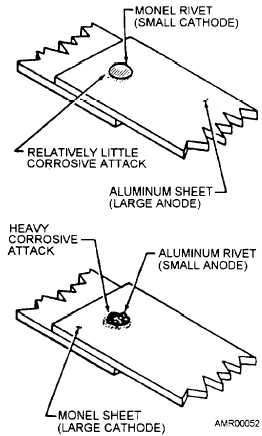

metals. (See figure 4-2.) If electrical contact develops

between two dissimilar metals, the corrosion attack on

the more active metal or anode (smaller size compared

to the less active one) will be severe and extensive. See

figure 4-2, bottom view. If the area of the less active

metal is small compared to the other, anodic attack will

be slight (fig. 4-2, top view).

Corrosion on avionics equipment is a continuing

process. The equipment does not have to be installed,

operating, or exposed to a particularly harsh

environment to corrode. The rate of the corrosion

process is determined by the temperature, humidity,

and chemicals in the environment. Moisture is the

single largest contributor in avionics corrosion. It

makes little difference whether the moisture is in the

form of vapor or liquid. Its affects are detrimental to

metals.

A clean aircraft retains its aerodynamic efficiency

and safety. Serious damage to the exterior and interior

surfaces of aircraft can result from the lack of correct

information about cleaning materials and equipment

and their use. Shipboard procedures are not

necessarily the same as procedures ashore, but the

same materials are available to produce comparable

results.

A problem you may face when fighting corrosion

is knowing what materials to use, where to find them,

and their limitations. You should use only those

materials that have military specifications. Corrosion

control information can be found in many directives

Figure 4-2.—Effects of area relationships in dissimilar metal

contacts.

4-3