time-consuming, and reduce equipment usage time.

These problems can be avoided through good

preventive maintenance practices and procedures.

To have good preventive maintenance practices

and procedures, you must know and be able to apply

the common types of corrosion prevention and

moisture protecting materials.

Q1. How does corrosion endanger aircraft or reduce

the margin of safety?

Q2. All maintenance personnel must be formally

Q3.

trained in what program?

What is the primary factor to consider when

selecting materials for constructing an aircraft?

on unpainted areas of working parts. Finally, shrouds,

covers, caps, and other mechanical equipment provide

varying degrees of protection from corrosive

mediums. However, none of these procedures will

provide 100-percent protection. Weathering causes

paint to oxidize and decay. Sealants may be worked

out by vibration or be eroded by rain and windblast.

Preservatives offer only temporary protection when

used on operating aircraft. The mechanical coverings

can be installed improperly or negligently.

Control of corrosion begins with an understanding

of the causes and the nature of corrosion. Corrosion is

CORROSION THEORY

in its most familiar form is a reaction between metal

and water, and is electrochemical in nature.

the process of electrochemical or direct chemical

attack on metals. The reaction is similar to that which

occurs when acid is applied to bare metal. Corrosion

LEARNING OBJECTIVES: Define the theory

of corrosion and its process. Identify the

publications and materials used in the

prevention of corrosion.

Metal corrosion is the decay of metals as they

combine with oxygen to form metallic oxides. Corrosion

is a chemical process that is the reverse of the process of

smelting the metals from their ores. Very few metals are

found in their pure state in nature. Most are found as

metallic oxides. These oxides have other undesirable

impurities in them. The refining process involves the

extraction of the base metal from the ore. The base metal

is then mixed with other elements (either metallic or

nonmetallic) to form alloys. Alloying elements are added

to base metals to develop a variety of useful properties.

For instance. in aircraft structural applications, high

strength-to-weight ratios are the most desirable

properties of an alloy.

After the base metals are refined, whether alloyed

or not, they have a potential to return to their natural

state. However, potential is not sufficient in itself to

begin and promote this reversion; a corrosive

environment must also exist. The significant element

of the corrosive environment is oxygen. The process

of oxidation (combining with oxygen) causes wood to

rot or bum and metals to corrode.

Control of corrosion depends upon maintaining a

separation between susceptible alloys and the

corrosive environment. This separation is

accomplished in various ways. A good intact coat of

paint provides most of the corrosion protection on

naval aircraft. Sealants used at seams and joints prevent

entry of moisture into the metal. Preservatives are used

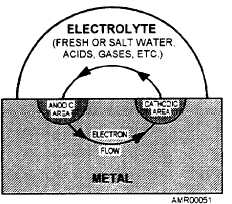

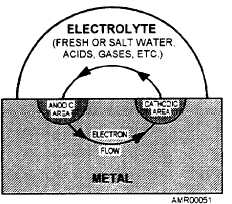

The electrochemical attack involves metals of

different electrical potential. These metals do not have

to be in direct contact. If one metal contains positively

charged ions and the other negatively charged ions, all

that is needed is an electrical conductor. When the

conductor is present, current will flow between the two

metals, as in the discharge of a dry-cell battery. In

electrochemical corrosion, the electrical conductor

may be any foreign material, such as water, dirt,

grease, or any debris that is capable of acting as an

electrolyte. The presence of salt in any of the foregoing

mediums accelerates the current flow and increases the

rate of corrosive attack.

Once an electrical connection is made, the electron

flow is established in the direction of the negatively

charged metal (cathode). This action eventually

destroys the positively charged metal (anode).

Preventive measures include avoiding the

establishment of the electrical circuit and removing

corrosion as soon as possible to avoid serious damage.

Figure 4-1 shows the electron flow in a corrosive

Figure 4-1.—Simplified corrosion cell.

4-2