CHAPTER 6

PRESSURE, TEMPERATURE, AND LEVEL CONTROL

DEVICES

The consoles on board gas turbine-powered ships

monitor and control various systems and equipment.

These systems are monitored with pressure,

temperature, and level gauges and meters. Control

d e v i c e s are used to accomplish the monitoring

functions. Control devices also generate the alarms that

are displayed on the consoles. A control device, in its

simplest form, is an electrical switching device that

applies voltage to or removes voltage from a single load.

In more complex systems, the initial device may set into

action other control devices that govern pressures,

temperatures, and liquid levels.

In this chapter we will describe the different control

devices that you, the GS, must troubleshoot and repair.

These include pressure, temperature, and level control

devices. Upon completion of this chapter, you should be

able to describe the types of control devices used on gas

turbine-powered ships and their basic maintenance

procedures.

PRESSURE CONTROL DEVICES

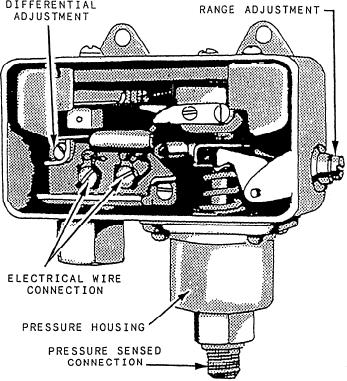

Figure 6-1.--Typical pressure switch.

Pressure is one of the basic engineering

measurements that must be monitored aboard ship.

P r e s s u r e control devices control the operation of

alarm to sound, or a piece of equipment to stop or start.

equipment. They stop and start motors, cycle ventilation

The switch is normally enclosed in a metal case with a

dampers, and generate low- and high-pressure alarms to

removable cover. The metal case provides a pressure

the propulsion control systems. Pressure control devices

port and an electrical connection point. A pressure

include pressure switches and pressure transducers.

switch converts pressure energy into electrical energy.

Pressure readings provided by these devices will allow

Pressure switches are used on pneumatic and hydraulic

you to determine the operating condition of your

systems. The shapes, configurations, and sizes of

equipment.

pressure switches may differ but the functions basically

the same. The type of switch used depends upon its

PRESSURE SWITCHES

application.

A pressure switch opens or closes a set of contacts

at a preset pressure. Pressure switches can provide alarm

Construction

indication or start an action, such as stopping an air

compressor at a preset pressure. A typical pressure

Pressure-operated switches are normally

switch is shown in figure 6-1.

single-pole, single-throw, quick-acting switches. An

individual pressure switch contains either a bellows or

The operation of the pressure switch is simple.

W h e n the pressure reaches the preset value, the

a diaphragm that works against an adjustable spring.

The spring causes the electrical contacts to open or close

pressure-sensing mechanism operates. The actuation of

automatically when the operating pressure rises or falls

the sensing mechanism causes a light to illuminate, an

6-1