from a specified value. A permanent magnet in the

differential. Bring the pressure to the value at which the

switch provides a positive snap when the contacts are

circuit is to be closed or opened. Turn the range

opened or closed. This snap action prevents excessive

adjustment screw slowly clockwise or counterclockwise

arcing at the contacts. The pressure at which the switch

until the contacts operate. This adjustment will set the

operates is adjustable within ranges, such as 0-15,

open or closing pressure.

15-50, and 50-100. This adjustment is made by using the

You have now brought the pressure to the point

range adjustment screw.

where the circuit will be activated. Since the differential

adjustment screw is now set at minimum, the circuit will

Maintenance

probably operate at a lower pressure than desired.

T h e r e f o r e , turn the differential adjustment screw

Normal maintenance performed on pressure

clockwise to widen the differential until the desired

switches is accomplished by using the PMS. This

activating pressure is obtained. Refer to the

maintenance includes inspecting the switch for damage,

manufacturer's technical manual for detailed

corrosion, and proper operation.

instructions on adjusting these switches.

When you inspect a pressure switch, look for any

physical external damage, such as loose-fitting covers,

Troubleshooting

d a m a g e d pressure and electrical connectors, and

missing parts. Check inside the metal case for corrosion

and the presence of water or oil. If water or oil is present,

After adjusting the operating range of pressure

check the condition of the rubber gasket in the cover and

switches, check the operation through at least one

replace it if necessary.

complete cycle. If you find a variation from the desired

During PMS, sometimes you must adjust the switch

operating values, go through the entire adjustment

to bring the operating values back in tolerance. To set a

procedure again. In an emergency, you can use the

pressure switch, you first have to set a known pressure

pressure of the system in which the switch is installed

in the working range of the switch. Normally, you do

instead of using the test setup. In this case, however, you

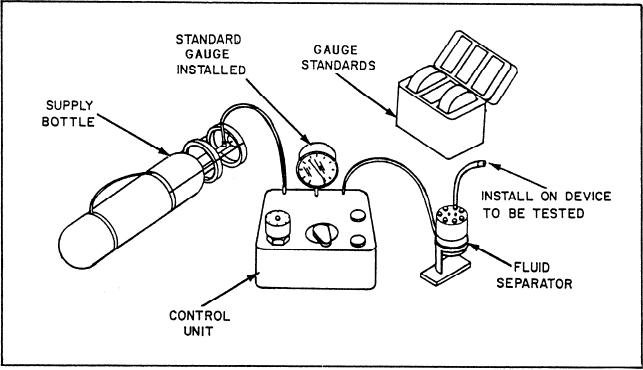

this by using a test setup, such as the one shown in figure

should reset the switch as soon as possible using the test

6-2. To set the operating range of the switch, turn the

setup. After adjusting the switch, watch the operation

differential adjustment screw (see fig. 6-1)

through another complete cycle. If you cannot adjust the

c o u n t e r c l o c k w i s e against the stop for minimum

switch, you must troubleshoot it.

Figure 6-2.--Setup for calibrating a pressure device.

6-2