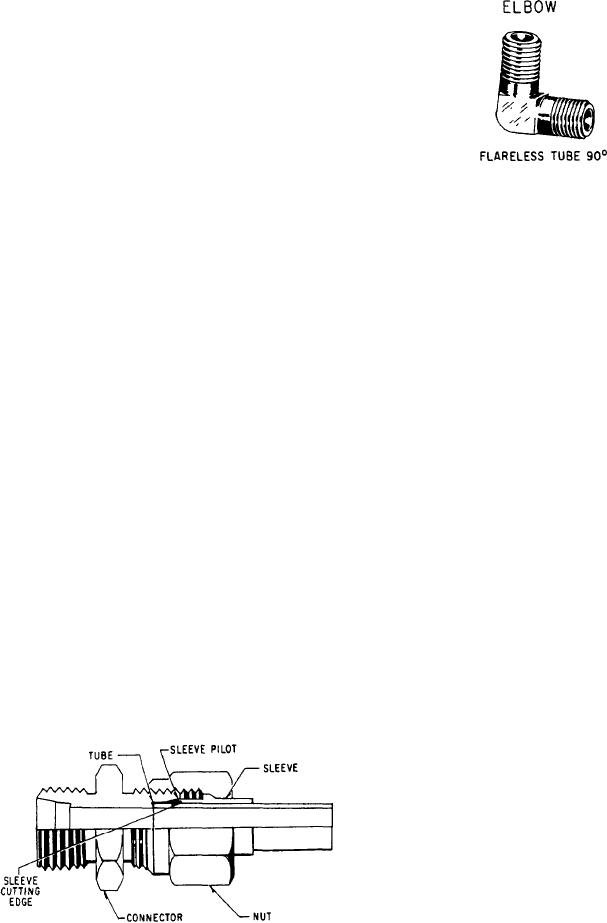

Flareless Fittings

Flareless fittings (figs. 6-44 and 6-45) are

suitable for use in hydraulic service and air

service systems at a maximum operating pressure

of 3000 psi and a maximum operating temperature

of 250F. Flareless fittings are installed to

conserve space and to reduce weight, installation

time, and system cleaning time. Do not use

flareless fittings if you do not have enough space

to properly tighten the nuts or if you have to

remove the equipment or piping for access to the

Figure 6-45.--Typical flareless fitting.

fittings. An exception to this rule is a gauge board.

It is designed so it may be removed as a unit for

piping, fluid, and insulation. They absorb the

repairs or alterations. Do not use flareless fittings

movements imposed by thermal expansion of the

where you cannot easily deflect the piping to

pipe and the motion of the ship. The pipe hangers

permit assembly and disassembly.

and supports prevent excessive vibration of the

Before assembly, ensure the tubing end is

piping and resilient mounts or other materials.

square, concentric, and free of burrs. For an

They are used in the hanger arrangement to break

effective fitting, be sure the cutting edge of the

all metal-to-metal contact to lessen unwanted

sleeve or ferrule bites into the periphery of the

sound transmissions.

tube; you can do this by presetting the ferrule.

One type of pipe hanger you need to become

familiar with is the variable spring hanger. This

FLANGE SAFETY SHIELDS

is used to support the ship's bleed air piping. It

provides support by directly compressing a spring

A fuel fire in the MER or an AMR can be

or springs. The loads carried by the hangers are

caused by a leak at a fuel oil or lube oil pipe flange

equalized by adjustment of the hangers when they

connection. Even the smallest leak can spray fine

are hot. These hangers have load scales attached

droplets of oil on nearby hot surfaces. To reduce

to them with a traveling arm or pointer that moves

this possibility, FLANGE SAFETY SHIELDS are

in a slot alongside the scale. This shows the degree

provided around piping flanges of inflammable

of pipe movement from cold to hot. The cold and

liquid systems, especially in areas where the fire

hot positions are marked on the load scale. You

hazard is apparent. The spray shields are usually

should check the hangers when they are hot to

made of aluminized glass cloth and are simply

ensure that the pointers line up with the hot

wrapped and wired around the flange.

position on the load scales. You can adjust

hangers that are out of position by loosening the

PIPE HANGERS

jam nut on the hanger rod and turning the

adjusting bolt of the hanger.

Pipe hangers and supports are designed and

located to support the combined weight of the

INSPECTIONS AND MAINTENANCE

Reasonable care must be given to the various

piping assemblies as well as to the units connected

to the piping systems. Unless the piping system

is in good condition, the connected units of

machinery cannot operate efficiently and safely.

You should be familiar with all the recommended

maintenance procedures and observe the safety

precautions when working on piping systems.

The most important factor in maintaining

piping systems in satisfactory condition is keeping

joints, valves, and fittings tight. To ensure this

condition, you need to make frequent tests and

inspections.

Figure 6-44.--Double-male flareless fitting.

6-32