packing makes it unsatisfactory for modem, high-

The centering ring is used as a reinforcement to

temperature, high-pressure equipment. Two types

prevent blowouts. The filler piece is replaceable.

of gaskets (metallic or semimetallic) are in use in

When renewing a gasket, you should remove this

present day high-temperature and high-pressure

piece from the retaining metal ring and replace

it with a new filler. Do not discard the solid metal

installations. Gaskets of corrugated copper or of

asbestos and copper are sometimes used on low-

retaining outer or centering ring unless it is

and medium-pressure lines.

damaged. You can compress the gaskets to the

thickness of the outer or centering ring.

Serrated-face metal gaskets (view B of fig.

When renewing a gasket in a flange joint, you

6-50) made of steel, Monel, or soft iron have

must exercise special precautions when breaking

raised serrations to make a better seal at the

piping flange joints. These gaskets have resiliency.

the joint, particularly in steam and hot water lines,

Line pressure forces the serrated faces tighter

or in saltwater lines that have a possibility of direct

connection with the sea. Be sure to observe the

against the adjoining flange. The gaskets shown

following precautions:

are of two variations.

Spiral-wound, metallic-asbestos gaskets (view

C of fig. 6-50) are made of interlocked strands

1. No pressure is on the line.

of preformed corrugated metal and asbestos

2. The line pressure valves, including the

strips, spirally wound together (normally called

bypass valves, are firmly secured, wired

the FILLER), and a solid metal outer or centering

closed, and tagged.

3. The line is completely drained.

ring (normally called the RETAINING RING).

4. At least two flange-securing bolts and nuts

diametrically opposite remain in place

until the others are removed, then

slackened to allow breaking of the joint,

and removed after the line is clear.

5. Precautions are taken to prevent explosions

or fire when breaking joints of flammable

liquid lines.

6. Proper ventilation is ensured before joints

are broken in closed compartments.

These precautions may prevent serious

explosions, severe scalding of personnel, or

f l o o d i n g of compartments. You should

thoroughly clean all sealing and bearing surfaces

for the gasket replacement. Check the gasket seats

with a surface plate, and scrape as necessary. This

affords uniform contact. Replace all damaged

bolt studs and nuts. In flange joints with raised

faces, the edges of gaskets may extend beyond the

edge of the raised face.

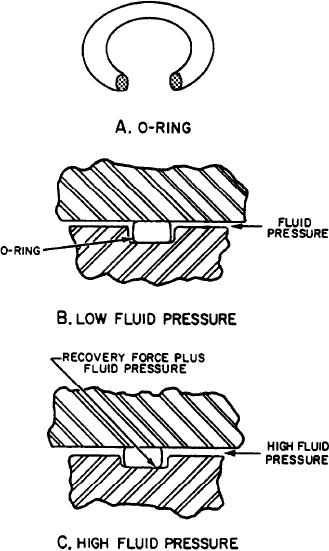

O-RINGS

Another method of preventing leakage in fluid

systems is by use of O-ring seals. Figure 6-51

shows an O-ring seal with two cross-sectional

views. An O-ring is a doughnut-shaped, circular

seal (view A of fig. 6-5 1) that is usually a molded

rubber compound. An O-ring seal has an O-ring

mounted in a groove or cavity (usually called a

gland).

When the gland is assembled (view B of fig.

6-51), the O-ring cross section is compressed.

When installed, the compression of the O-ring

Figure 6-51.--O-ring seal with two cross-sectional views.

6-36