flattens, or straightens, a spring section. Many

types of spring nuts use curved metal springs,

bellows, and coil springs. All spin on and off

without locking until the pressure against the

working surface straightens the spring.

You should always consult equipment

manuals for the proper torque value. Be sure

threads are always clean and lightly lubricated

with the proper lubrication. Discard any with

damaged threads.

Figure 6-57.--Helical spring lockwasher.

Spring Beam Nuts

down. When torqued, it acts as a flat washer

Spring beam nuts (fig. 6-56) are formed with

contributing normal friction for locking the screw

a light taper in the threads toward the upper

or bolt and the working surface; it also maintains

portion of the nut. Slots are cut in the outer

the tension on the bolt. Because of the helical

portion, forming segments that can be forced out-

spring lockwasher's small diameter, it is usually

ward when the nut is installed. Elastic reaction

not used on soft materials or with oversized or

causes the segments to push inward, gripping the

elongated holes.

bolt. Like the nylon insert nut, this nut does not

deform the bolt threads and can be used on

Curved or Conical Spring Lockwashers

frequently removed items. If you can thread the

nut past the deflection segments without a wrench,

Curved or conical spring lockwashers have

discard the nut and replace it with a new one.

almost the same properties as the helical spring

lockwasher. They provide a constant tension on

LOCKWASHERS

the bolt or screw when loosened. The tension

Many installations on board naval ships still

produced is usually less than that produced by the

use lockwashers to prevent threaded fasteners

helical spring lockwasher. Like any locking device

from loosening. If loosening has not been a

relying on tension, spring lockwashers may loosen

problem, you may replace worn lockwashers with

on shock loading. When the bolt stretches more

an identical type; however, if loosening has been

than the spring distortion from the shock loading,

a problem, you should use self-locking fasteners

the washer serves no further purpose. Recheck the

instead of lockwashers.

washer, where possible, when shock is sufficient

The most common lockwasher used is the

to suspect loosening. Some spring lockwashers

helical spring washer. Other types are the conical

have teeth on the outer edge. These teeth do not

and toothed tab.

aid in locking, but they prevent side slippage and

turning.

Helical Spring Lockwashers

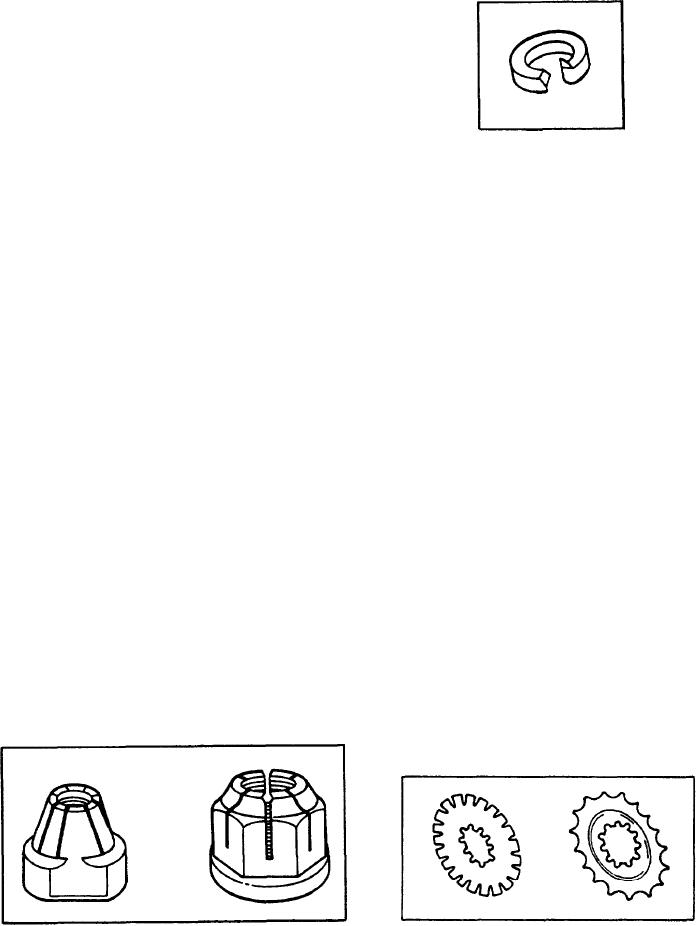

Toothed Lockwashers

The helical spring lockwasher (split ring)

(fig. 6-57) is flattened when the bolt is torqued

Toothed lockwashers (fig. 6-58) have teeth that

are twisted or bent to prevent loosening. Cutting

Figure 6-58.--Toothed lockwashers.

Figure 6-56.--Spring beam nuts.

6-39