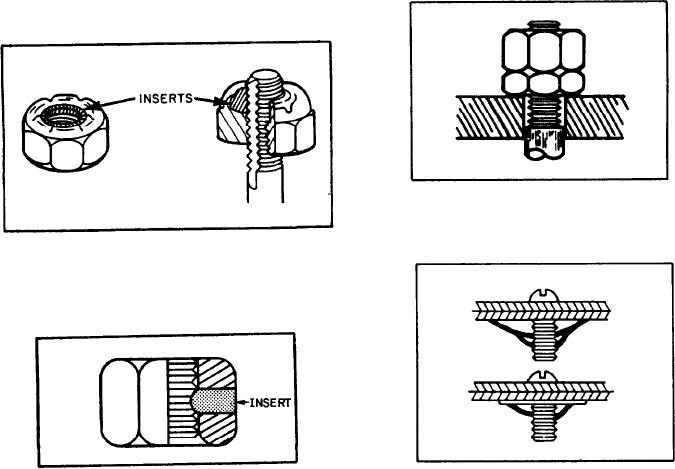

They force the nut to the side, cocking it slightly.

LOCKNUTS

This produces frictional forces on one side of the

Locknuts are used in special applications

bolt thread. Although the plastic insert locks

where you want to ensure that the components

without seating, proper torque applied to the nut

joined by the fasteners will not loosen. Two types

stretches the bolt, creating clamping forces that

of locknuts are in common use. The first type

add to the locking abilities of the nut. Before

applies pressure to the bolt thread and can be

reusing nylon insert nuts (fig. 6-53), check the

used where frequent removal may be required.

inserts. If worn or torn, discard the nut. Install

The second type deforms the bolt thread and is

the nut (on clean lightly lubricated threads) finger

used only where frequent removal is unnecessary.

tight. If you can install the nut to the point where

The first type includes plastic ring nuts, nylon

the bolt threads pass the insert without a wrench,

insert nuts, jam nuts, spring nuts, and spring

discard the nut and use a new one.

beam nuts. The second type includes distorted

collar nuts and distorted thread nuts; they are not

Jam Nuts

commonly found in gas turbine equipment and

You should install jam nuts (fig. 6-54) with

will not be covered in this section.

the thinner nut to the working surface and the

Plastic Ring Nuts

thicker nut to the outside. The thin nut is

deformed by the wider nut and pressed against

Plastic ring nuts (fig. 6-52) deform the plastic

the working surface and threads.

insert when they are installed. The resilient plastic

material is forced to assume the shape of the

Spring Nuts

mating threads, creating large frictional forces.

Spring nuts (fig. 6-55) lock by the side grip

Nylon Insert Nuts

on the bolt. When tightened, the spring nut

Nylon insert nuts have plastic inserts (plugs)

that do not extend completely around the threads.

Figure 6-54.--Jam nuts.

Figure 6-52.--Plastic ring nut.

Figure 6-55.--Spring nuts.

Figure 6-53.--Nylon insert nut.

6-38