PACKING AND

Piping should be tested at the frequency and

GASKET MATERIAL

test pressure specified following the PMS and the

applicable equipment technical manual. Test

Packing and gasket materials are required to

pressure must be maintained long enough to show

seal joints in steam, water, gas, air, oil, and other

any leaks or other defects in the system.

lines and to seal connections that slide or rotate

Instruction manuals should be available and

under normal operating conditions. There are

followed for the inspection and maintenance of

many types and forms of packing and gasket

piping systems and associated equipment;

materials available commercially.

however, if the manufacturer's instruction manual

is not available, you should refer to Naval Ships'

PACKING AND GASKET SELECTION

Technical Manual, chapter 505, for details of

To simplify the selection of packing and gasket

piping inspection and maintenance.

materials commonly used in naval service, the

Naval Sea Systems Command has prepared a

PIPING SYSTEM

packing and gasket chart, Mechanical Standard

IDENTIFICATION MARKING

Drawing B-153 (see fig. 6-47 at the end of

this chapter). It shows the symbol numbers and

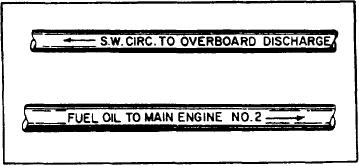

All piping should be marked to show the name

the recommended applications for all types and

of the service, destination (where possible), and

kinds of packing and gasket materials.

direction of flow (fig. 6-46).

The symbol number used to identify each type

The name of the service and destination should

of packing and gasket has a four-digit number.

be painted on by stencil or hand lettering, or by

(See List of Materials in fig. 6-47.) The first digit

application of previously printed, stenciled, or

shows the class of service with respect to fixed and

lettered adhesive-backed tape. Lettering will be

moving joints; the numeral 1 shows a moving joint

1 inch high for a 2-inch or larger outside diameter

(moving rods, shafts, valve stems), and the

bare pipe or insulation, For smaller sizes,

numeral 2 shows a fixed joint (flanges, bonnets).

lettering size may be reduced or label plates

The second digit shows the material of which the

attached by wire or other suitable means.

packing or gasket is primarily composed--

Direction of flow will be indicated by an

asbestos, vegetable fibre, rubber, metal, and so

arrow 3 inches long pointing away from the

forth. The third and fourth digits show the

lettering. For reversible flow, arrows are to be

different styles or forms of the packing or gasket

shown on each end of the lettering.

made from the material.

Black is used for lettering and arrows.

Practically all shipboard packing and gasket

However, on dark-colored pipe (including oxygen

problems can be solved by selection of the

piping), white is used.

correct material from the listings on the packing

Markings will be applied to piping in

and gasket chart. The following examples show

conspicuous locations, preferably near the

control valves and at suitable intervals so every

the kind of information that you can get from the

packing and gasket chart.

line will have at least one identification marking

Suppose you are required to repack and

in each compartment through which it passes.

install a valve in a 150-psi seawater service system.

Piping in cabins and officers' wardrooms will not

Refer to figure 6-47, the packing and gasket chart.

normally be marked.

Under the subhead Symbols and Specifications

for Equipments, Piping and Independent Systems,

you find that symbol 1103 indicates a suitable

material for repacking the valve. Notice that the

first digit is numeral 1, indicating that the material

is for use in a moving joint. Under the List of

Materials, you find the packing is asbestos rod,

braided.

For installing the valve, you need proper

gaskets. By use of the same subhead, you find that

symbols 2150, 215l type II, 2152, and 2290 type

II are all suitable for installing the valve. Notice

that the first digit is numeral 2, which indicates

that it is designed for fixed joints. Again, by

Figure 6-46.--Pipe markings.

6-33