FITTINGS

Reusable End Fittings-There is no

shelf life for end fittings. They should

Some type of connector must be provided to

be replaced on an individual basis

attach the pipe, tube, or hose to the other

when examination makes them suspect.

components of the system and to connect sections

of the line to each other. There are many different

types of connectors (commonly called fittings)

Servicing

provided for this purpose. Some of the most

common types of fittings are covered in the

No servicing or maintenance is required since

following paragraphs.

hose or fittings must be replaced at the slightest

suspicion of potential failure. If a fitting is

removed from a section of hose, that hose

Threaded Joints

section must not be reused, regardless of its

service life.

The threaded joints are the simplest type of

pipe fittings. Threaded fittings are not widely used

aboard modern ships except in low-pressure water

Service Life of Rubber Hose

piping systems. The pipe ends connected to the

union are threaded, silver-brazed, or welded

into the tail pieces (union halves); then the two

All rubber hose has a periodic replacement

ends are joined by setting up (engaging and

time. All flexible rubber hose connections will be

tightening up on) the union ring. The male and

replaced every 5 years ( 6 months) in critical

female connecting ends of the tail pieces are

systems and every 12 years in noncritical systems.

Wire braided Teflon hose has no specified

carefully ground to make a tight metal-to-metal

fit with each other. Welding or silver-brazing the

shelf or service life. Its replacement is based on

ends to the tail pieces prevents contact of the

inspection of the hose for excessive wear or

damage.

carried fluid or gas with the union threading.

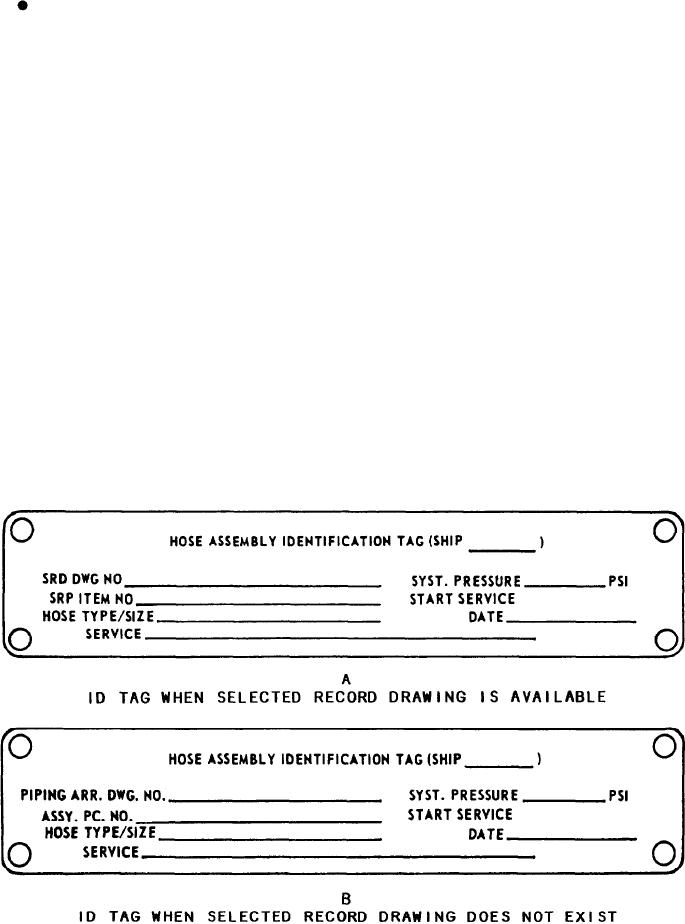

Figure 6-38.--Hose assembly identification tags.

6-29