assemblies are constructed of rubber or Teflon .

A casual inspection of a badly scaled zinc

Each of these materials has its own distinct

anode, especially while it is still wet, may lead

advantages or disadvantages, depending upon its

personnel to believe that the metal is exposed

application.

instead of the scale. The anode, even though it

Steel piping and tubing are relatively in-

appears to be in good condition, should be cleaned

with a chipping hammer to learn the true

expensive, have a high tensile strength, are suitable

condition of the metal. Whenever zincs are

for bending and flanging, and are very adaptable

to high pressures and temperatures. Its chief

inspected or cleaned, check the condition of the

disadvantage is a comparatively low resistance to

metallic contact between the anode and its

support.

corrosion.

Copper and brass piping and tubing have a

high resistance to corrosion and are easily drawn

PIPING

or bent. Pipe or tubing made from these materials

is unsuitable for systems with high temperatures,

The control and application of fluid power

stress, or vibration because they have a tendency

would be impossible without a suitable means of

to harden and break.

conveying the fluid from the power source to the

Aluminum has many characteristics and

point of application. Fluid lines used for this

qualities required for fluid systems. It has a high

purpose are called piping. They must be designed

resistance to corrosion, is lightweight, is easily

and installed with the same care applicable to

drawn or bent, and (when combined with certain

other components of the system. To obtain this

alloys) will withstand high pressures and

desired result, attention must be given to the

temperatures.

various types, materials, and sizes of lines

Stainless steel piping or tubing is relatively

available for the fluid power system. The different

lightweight and is used in a system that will be

types of lines and their application to fluid power

exposed to abrasion, high pressure, and intense

systems are described in the first part of this

heat. Its main disadvantage is high cost.

section. The last part of this section is devoted

to the various connectors applicable to the

FLEXIBLE HOSE ASSEMBLIES

different types of fluid lines.

The flexible hose assembly is a specific type

IDENTIFICATION OF PIPING

of flexible device that uses reinforced rubber hose

The three most common lines used in fluid

power systems are pipe, tubing, and flexible hose.

They are sometimes referred to as rigid (pipe),

semirigid (tubing), and flexible piping. In

commercial usage, there is no clear distinction

between piping and tubing, since the correct

designation for each product is established by the

manufacturer. If the manufacturer calls its

product pipe, it is pipe; if the manufacturer calls it

tubing, it is tubing.

In the Navy, however, a distinction is made

between pipe and tubing. The distinction is based

on the method used to determine the size of the

product. There are three important dimensions

of any tubular product-outside diameter (OD),

inside diameter (ID), and wall thickness. The

product is called tubing if its size is identified by

actual measured outside diameter and by actual

wall thickness. The product is called pipe if its

size is identified by a nominal dimension and wall

thickness.

PIPING MATERIALS

The pipe and tubing used in fluid systems

today are commonly made from steel, copper,

brass, aluminum, and stainless steel. The hose

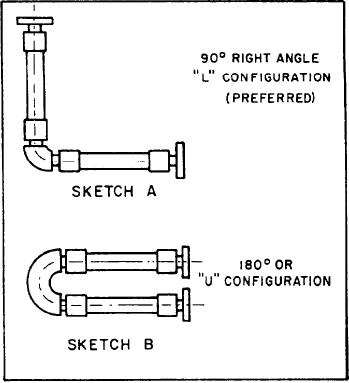

Figure 6-36.--90 and 180 flexible hose configurations.

6-24