When working with batteries, ensure you wear

proper protective clothing (such as safety glasses,

rubber gloves, rubber apron, and rubber boots).

The battery water contains acids which can ruin

clothes and cause severe burning. Be sure you

follow the safety precautions found in Naval

Ships' Technical Manual, Chapter 313, "Portable

Storage and Dry Batteries," and those found on

the PMS card.

HOISTING AND LIFTING DEVICES

When performing maintenance, you may have

to move or lift some of the heavy equipment or

components. You can use various devices to do

this. The selection of the proper device depends

on many factors, such as the equipment to be

moved and the available work space. A working

knowledge of the following devices will aid you

in selecting the right device.

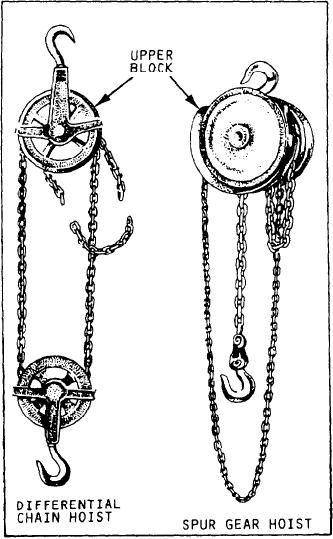

CHAIN HOISTS

Chain hoists (chain falls) provide an easy and

efficient method for hoisting loads by hand. The

advantages of chain hoists are that one person can

raise a load of several tons, and the load can

remain stationary without being secured. A chain

hoist permits small movements, accurate adjust-

ment of height, and gentle handling of loads.

For these reasons they are particularly useful

in hoisting motors or parts which must be

precisely aligned with other parts. Two of the

most common types used for vertical hoisting

Figure 3-41.--Chain hoists.

operations are the differential chain hoist and the

spur gear hoist (fig. 3-41). The load capacity of

Before using a chain hoist, inspect it to

a chain hoist can range from 1/2 ton to 40 tons

ensure safe operation. Replace a hook that shows

and is stamped on the shell of the upper block.

signs of spreading or excessive wear. If links in

The differential chain hoist is suitable for light

the chain are distorted, the chain hoist has

loads. This hoist is only about 35 percent efficient.

probably been overloaded. Make sure the hoist

In other words, about 35 percent of the energy

is in good repair before attempting to lift a load.

that you exert is converted into useful work for

lifting the load. The remaining 65 percent of the

HAND-OPERATED RATCHET

bearings, and chains.

LEVER HOISTS

The spur gear hoist is used for operations that

require frequent use of a hoist and where few

personnel are available to operate it. The spur gear

more commonly called come-a-longs, are similar

hoist is about 85 percent efficient.

to the chain hoist. The main difference is that you

The lower hook is usually the weakest part in

operate a ratchet handle to move the load vice a

the assembly of a chain hoist. This is intended as

chain. The direction of movement is changed by

a safety measure so the hook will start to spread

a lever on the side of the unit or in the handle.

open if overloaded. Thus, you must closely watch

Compared to the chain hoist, the come-a-long

the hook to detect any sign of overloading in time

is smaller because of the size difference of the top

to prevent damage.

3-30