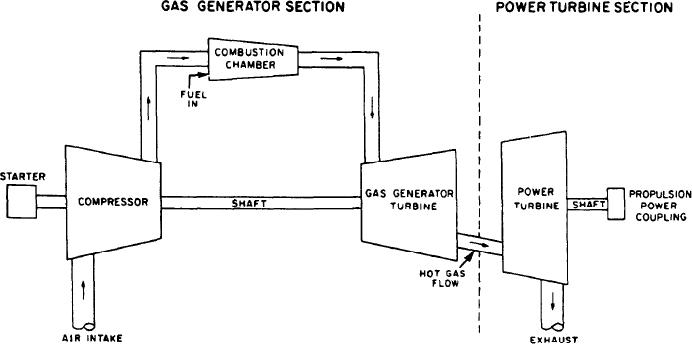

Figure 1-21.--Split-shaft engine.

The short length of the can-annular type of

is connected directly to the same turbine rotor that

chamber provides minimal pressure drop of the

drives the compressor. Usually, a speed decreaser

gases between the compressor outlet and the flame

or reduction gear is located between the rotor and

area. The relatively cool air in the annular outer

the power output shaft. A mechanical connection

can reduces the high temperatures of the inner

still exists throughout the engine.

cans. This air blanket keeps the outer shell of the

combustion section cooler. Maintenance on the

In the split-shaft engine (fig. 1-21), no

burners is simple. You can remove and inspect

mechanical connection exists between the GG

any number of burners just by sliding the case

turbine and the PT. In this type of engine, the

back.

output speed is varied by variation of the

generator speed. Also, under certain conditions,

the GG can run at a reduced rpm and still provide

CLASSIFICATION BY

maximum PT rpm. The reduced rpm greatly

improves fuel economy and also extends the life

TYPE OF SHAFTING

of the GG turbine. The starting torque required

Several types of GTE shafts are used. These

is lowered because the PT, reduction gears, and

are single shaft, split shaft, and twin spool. Of

output shaft are stationary until the GG reaches

these, the single shaft and split shaft are the most

approximate idle speed. Another feature of the

common in use in naval vessels. The twin-spool

multishaft marine propulsion plant is the GG

-shaft is currently used for marine military applica-

rotates only one way. One design (clockwise

tion only on the U.S. Coast Guard Hamilton class

rotation or counterclockwise rotation) of the GG

cutters, which use the Pratt-Whitney FT-4 twin-

can be used on either shaft and still allow the PT

spool GTE.

to rotate either way. This is done by changing the

In current U.S. Navy service, the single-shaft

PT wheel and nozzles. The arrangement shown

engine is used primarily for driving ship's service

in figure 1-21 is typical for propulsion GTEs

generators. The split-shaft engine is used for main

aboard today's ships.

propulsion, as a variety of speed ranges is

encountered.

The twin-spool type of GTE is sometimes

referred to as a multistage GTE. It has two

Figure 1-20 is a block diagram of a single-shaft

GTE. In the engine shown, the power output shaft

separate compressors and two separate turbine

1-19