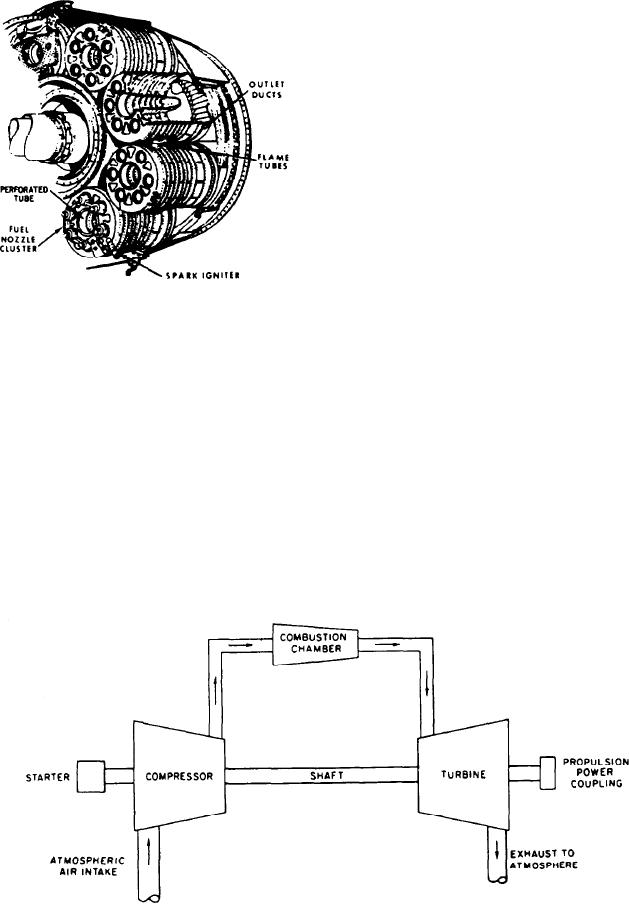

Can-Annular Chamber

The can-annular type of combustion chamber

combines some of the features of both the can

and the annular burners. The can-annular type

of chamber design is a result of the split-spool

compressor concept. Problems were encountered

with a long shaft and with one shaft within the

other. Because of these problems, a chamber was

designed to perform all the necessary functions.

In the can-annular type of chamber, individual

cans are placed inside an annular case. The cans

are essentially individual combustion chambers

(fig. 1-19) with concentric rings of perforated

holes to admit air for cooling. On some models

each can has a round perforated tube that runs

down the middle of the can. The tube carries

additional air, which enters the can through the

Figure 1-19.--Can-annular type of combustion chamber.

perforations to provide more air for combustion

and cooling. The effect is to permit more

burning per inch of can length than could

Large holes and slots are located along the

otherwise be done.

liners. They (1) admit some cooling air into the

Fuel nozzle arrangement varies from one

combustion space to help cool the hot gases to

nozzle in each can to several nozzles around the

a safe level, (2) center the flame, and (3) admit

perimeter of each can. The cans have an inherent

the balance of air for combustion.

resistance to buckling because of their small

The annular-type combustion chamber is a

diameter. Each can has two holes that are opposite

very efficient system that minimizes bulk and can

each other near the forward end of the can. One

be used most effectively in limited space. There

hole has a collar called a flame tube. When the

are some disadvantages. On some engines, the

cans are assembled in the annular case, these holes

liners are one piece and cannot be removed

and their collars form open tubes. The tubes are

without engine disassembly. Also, engines that use

between adjacent cans so a flame passes from one

a one-piece combustor dome must be disassembled

can to the next during engine starting.

to remove the dome.

Figure 1-20.--Single-shaft engine.

1-18