Figure 1-24.--Turbine rotor elements.

Figure 1-23.--Cutaway view of a turbine stator.

nozzle converts a varying portion of the heat and

pressure energy to velocity energy. The velocity

energy can then be converted to mechanical energy

through the rotor blades.

The turbine nozzle functions to deflect the

gases to a specific angle in the direction of

turbine wheel rotation. The gas flow from the

nozzle must enter the turbine blade passageway

while it is still rotating, making it essential

to aim the gas in the general direction of turbine

rotation.

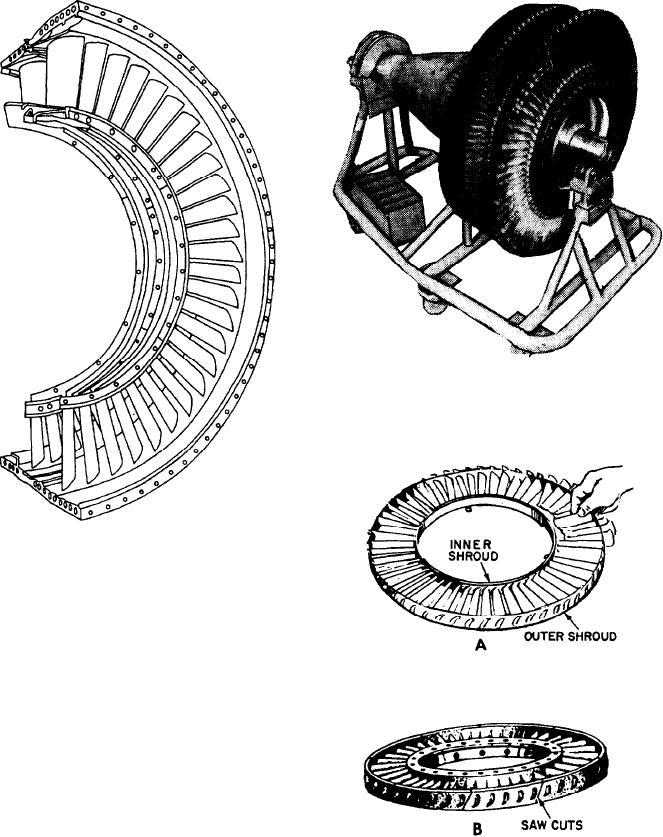

The turbine nozzle assembly has an inner

shroud and an outer shroud between which

are fixed the nozzle vanes. The number of

Figure 1-25.--Turbine nozzle assemblies. A. Loose-fitting

vanes varies with different types and sizes

vanes. B. Welded vanes.

of engines. Figure 1-25 shows typical turbine

nozzle assemblies.

1-21