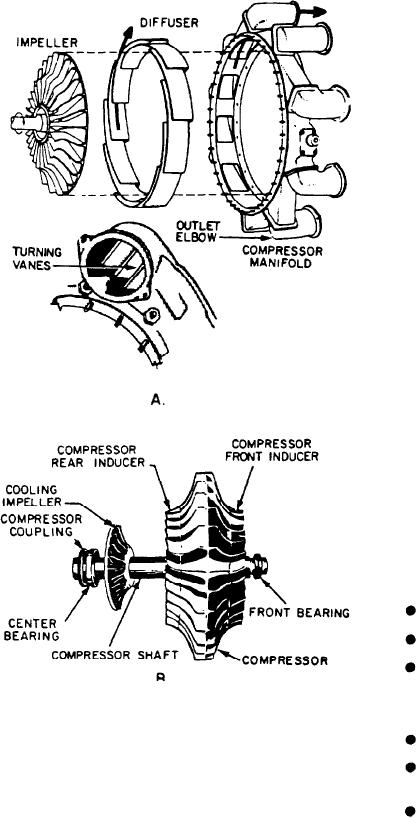

PRINCIPLES OF OPERATION.--The com-

pressor draws in the air at the hub of the impeller

and accelerates it radially by centrifugal force

through the impeller. It leaves the impeller at a

high velocity and a low pressure and flows

through the diffuser (fig. 1-10, view A). The

diffuser converts the high-velocity, LP air to low-

velocity, HP air. The compressor manifold diverts

the flow of air from the diffuser (an integral part

of the manifold) into the combustion chambers.

CONSTRUCTION. --In a centrifugal com-

pressor the manifold has one outlet port for each

combustion chamber. The outlet ports are bolted

to an outlet elbow on the manifold (fig. 1-10,

view A). The outlet ports ensure that the same

amount of air is delivered to each combustion

chamber. Each outlet port elbow contains from

two to four turning vanes to change the airflow

from radial to axial flow and to reduce air

pressure losses by presenting a smooth turning

surface.

The impeller is usually made from a forged

aluminum alloy that is heat-treated, machined,

and smoothed for minimum flow restriction and

turbulence. Some types of impellers are made

from a single forging, while in other types the

inducer vanes are separate pieces that are welded

in place.

Centrifugal compressors may achieve effi-

ciencies of 80 to 84 percent at pressure ratios of

2.5:1 to 4:1 and efficiencies of 76 to 81 percent

at pressure ratios of 4:1 to 10:1.

Some advantages of centrifugal compressors

are as follows:

Rugged, simple in design

Relatively light in weight

Develop high-pressure ratio per stage

Some disadvantages of centrifugal compressors

are as follows:

Figure 1-10.--Centrifugal compressors. A. Single entry.

B. Dual entry.

Large frontal area

L o w e r efficiency than axial-flow

Dual-entry impellers are smaller in diameter

compressors

and rotate at higher speeds to ensure a sufficient

Difficulty in using two or more stages due

airflow. Most modern GTEs use the dual-entry

to the air loss that occurs between stages

compressor to reduce engine diameter. Because

and seals

the air must enter the engine at almost right angles

to the engine axis, a plenum chamber is required

Axial-Flow Compressors

for dual-entry compressors. The air must

surround the compressor at a positive pressure

The purpose of the axial compressor is the

before entering the compressor to ensure an

same as the centrifugal compressor. They both

undisturbed flow.

1-11