shaft. The lip seals are used where relatively low

the carbon rings. The air pressure is forced out

speeds and temperatures are encountered.

along the shaft in both directions. The pressure

prevents oil from entering the compressor or

Two disadvantages of the lip-type seals are

turbine and combustion gases from reaching the

that (1) they will seal against only little or no fluid

pressure, and (2) they are easily damaged. A burr

bearings. The main disadvantage of this seal is

on the shaft or dirt can tear the seal and cause

minor oil leakage that occurs during start-up and

leakage.

run down as the oil pump moves oil before enough

airflow prevents leakage. However, the leakage

LABYRINTH/WINDBACK SEAL.--The

is so slight that the engine normally will reach its

designated overhaul hours of operation before oil

labyrinth/windback seals (fig. 1-37) combine a

rotating seal having oil slingers and a serrated

accumulation will have any effects.

surface with a stationary seal having windback

threads and a smooth rub surface. The oil slingers

STARTING SYSTEMS

throw oil into the windback threads, which direct

the oil back to the sump area. The serrations cut

The GTEs use a starter to turn the compressor

grooves into the smooth surface of the stationary

at sufficient speed to initiate and sustain

seal to maintain close tolerances throughout a

combustion. Both the compressor and the GG

large temperature range. This seal allows a small

turbine must spin. In starting dual axial-flow

amount of seal pressurization air to leak into the

compressor engines, the starter needs to rotate

sump, thereby preventing oil leakage.

only the HP compressor. The starter's first

requirement is to accelerate the compressor to

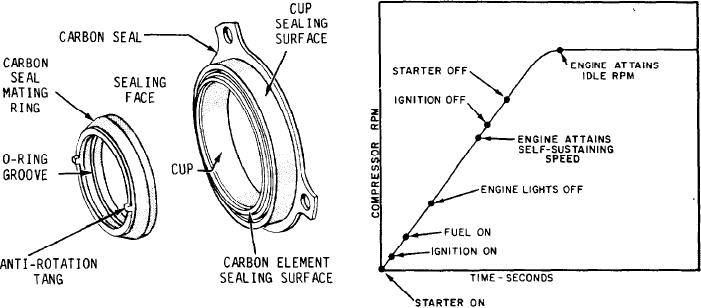

CARBON RING SEAL.--The carbon seal

provide enough airflow and pressure to support

(fig. 1-38) has a stationary, spring-loaded, carbon

combustion in the burners.

Once fuel has been introduced and the engine

sealing ring and a rotating, highly polished steel

mating ring. It prevents oil in the gearbox from

has fired, the starter must continue to accelerate

leaking past the drive shafts of the starter, fuel

the compressor above the self-sustaining speed of

pump, and auxiliary drive pad.

the engine. The starter must provide enough

Another form of the carbon seal is also in use.

The carbon rings are not spring-loaded. They

and air loads of the engine.

Figure 1-39 shows a typical starting sequence

move freely around the shaft and seal axially

against the housing. When the engine is up to

for a GTE. When the starter has accelerated the

speed, the rings center themselves radially in the

compressor enough to establish airflow through

housing. Compressor bleed air is forced between

Figure 1-39.--Typical starting sequence for a GTE.

Figure 1-38.--Carbon ring seal.

1-31