the engine, the ignition is turned on and the fuel

valves are opened. The sequence of the starting

procedure is important. At the time the fuel/air

mixture is ignited, enough airflow must pass

through the engine to support combustion.

After the engine has reached its self-sustaining

or self-accelerating speed, the starter can be

deactivated. If the starter is cut off below the

self-sustaining speed, the engine may decelerate

because it doesn't have enough energy to

overcome its own friction and operating losses.

It may also suffer a "hung start" in which it idles

at a speed so low that it is unable to accelerate

enough to obtain proper operating parameters.

A hung-start engine will overheat because of a

lack of cooling air. The starter must continue to

boost engine speed well above self-sustaining

speed to avoid hot or hung (false) starts, or a

combination of both. In a hot start, the engine

lights off, but because of a lack of adequate

cooling and combustion air, the exhaust gas

temperature exceeds the allowable limit for the

engine.

At the proper points in the starting sequence,

the starter and, usually, the ignition system will

cut off. The higher the rpm before the starter cuts

out, the shorter will be the total time required for

the engine to attain idle rpm. This is because the

engine and the starter are working together.

All GTE starters must be able to produce

enough torque to start the engine properly. The

GTEs must reach a certain minimum idle rate for

a start to be satisfactory. This requires the

torque characteristics of an acceptable starter to

exceed by a good margin the amount of torque

needed to overcome friction.

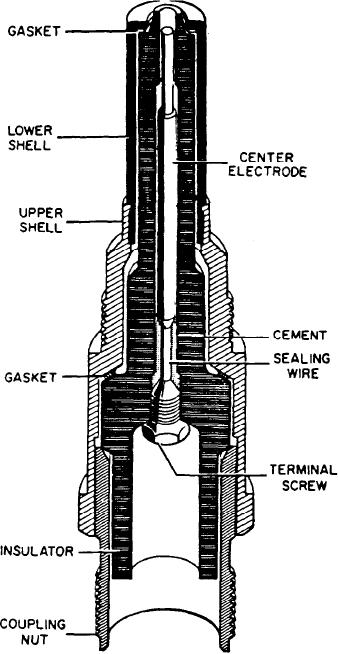

Figure 1-40.--Spark igniter.

The GTEs use three basic types of starters

and starter systems--electric, hydraulic, and

pneumatic. Pneumatic (air-turbine) starters are

SPARK IGNITER SYSTEM

the most commonly used on all except smaller

engines, which generally use electric starters. Some

Once adequate airflow has been established

marine GTE installations use hydraulic starters.

through the combustion area, fuel can be injected

and the spark igniters start the burning process.

Another type of starter system is the air

The spark igniters are high-voltage electrical spark

impingement system. Bleed air from another GTE

producers powered from the ignition exciter

is used directly in the HP turbine assembly to

circuits.

rotate the GG. Due to the volume of air required,

The ignition exciter derives its input power

the air impingement system is used primarily in

from the ship's service 60-Hz, 115-volt electrical

starting aircraft engines and will not be covered

system. Its function is to produce a high-energy

in any further detail. We will describe the

spark at the spark igniter in the engine. This must

pneumatic starter system in chapter 2 of this

be accomplished with a high degree of reliability

TRAMAN.

1-32