scavenge, and sump vent. We will discuss these

subsystems and their components in chapter 2.

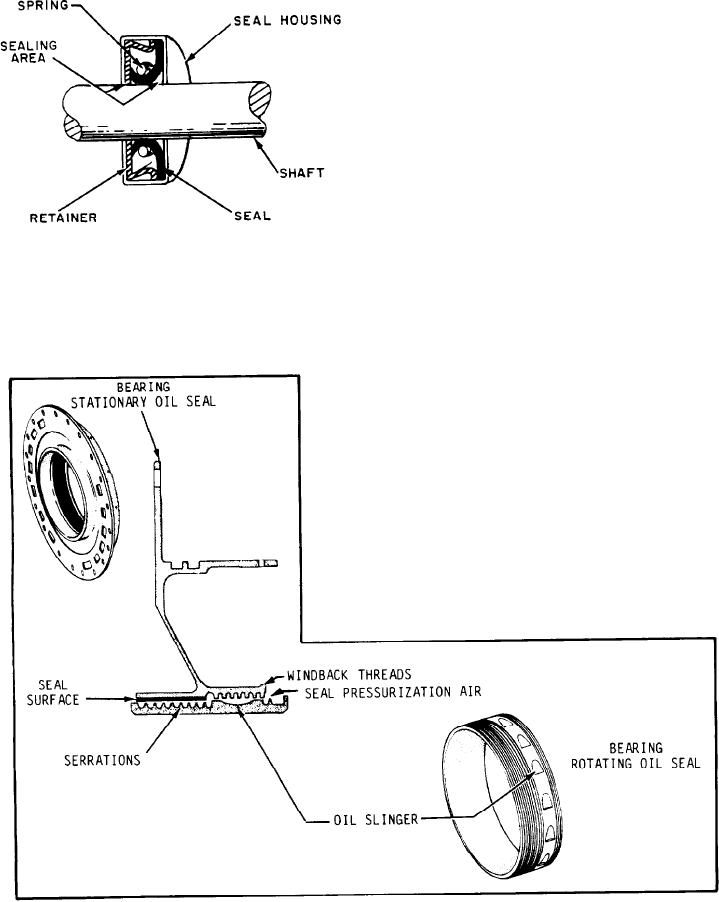

Oil Seals

Three types of oil seals are common to the

GTEs, the lip-type seal, the labyrinth/windback,

and the carbon ring.

LIP-TYPE SEAL.--The lip-type seal (fig.

1-36) is used to prevent leakage in one direction

only. A metal frame is covered with a synthetic

material, usually neoprene. The neoprene is

somewhat smaller than the shaft. The elasticity

of the neoprene will allow the shaft to slide

through the seal. The seal is molded with a lip to

retain a spring around the center. The spring keeps

a snug fit around the shaft. The construction of

Figure 1-36.--Lip-type seal.

the lip-type seal allows for some very slight

misalignment and for axial movement of the

Figure 1-37.--Labyrinth/windback seal.

1-30