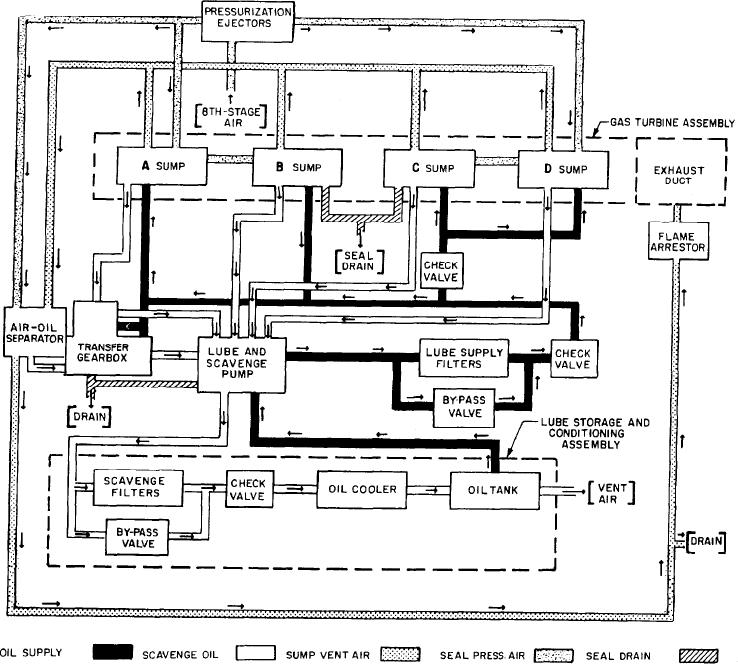

Figure 1-35.--Lubrication system schematic (typical).

of lube oil to the bearing at all engine speeds. This

and the splines. Separate scavenge elements in the

is sometimes known as a calibrated oil system.

lube and scavenge pump remove oil from the

Since lube oil is supplied to the various parts of

sumps and the transfer gearbox (accessory drive).

the system under pressure, provision is made to

prevent the oil from leaking into unwanted areas,

The scavenged oil is returned to the lube storage

such as the compressors and turbines. This is

and conditioning assembly where it is filtered,

usually accomplished by use of lip-type seals,

cooled, and stored. Scavenge oil is filtered by a

duplex filter mounted on the lube storage tank.

labyrinth oil seals, or carbon ring pneumatic oil

seals. We will discuss these seals in detail later in

this section.

Lubrication System Subsystems

The lubrication system provides the GTE

The lubrication system is usually divided into

three subsystems identified as lube supply, lube

oil to prevent excessive friction and heat. Oil

1-29