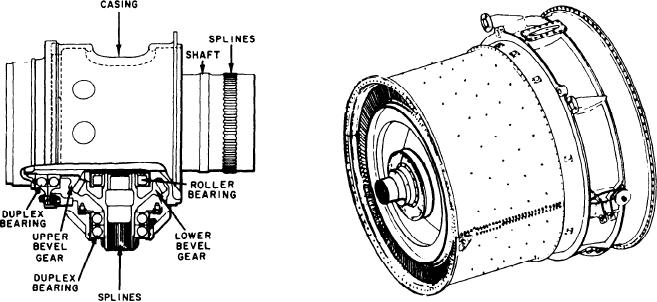

a shaft, a pair of bevel gears, bearings, and oil

casing, an air/oil separator, gears, bearings,

jets (not shown). Two duplex ball bearings and

seals, oil nozzles, and accessory adapters. The

a roller bearing are mounted in the casing. The

accessories are the fuel pump, main fuel control

casing is bolted inside the front frame hub and

(MFC), lube and scavenge pump, air/oil

has internal oil passages and jets to provide

separator, and starter. All except the air/oil

separator are mounted on the aft section (fig.

which rotates on a horizontal axis, is splined at

2-35, view B). The aft section of the TGB is

the aft end to mate with the second-stage disk of

the AGB. An access cover in the bottom of the

the compressor rotor. The forward end of the

casing allows easy removal and installation of

shaft mounts the upper bevel gear and is

the radial drive shaft. Also, an access cover is on

supported by a duplex ball bearing. The lower

the manual drive pad. This feature allows access

bevel gear rotates on a vertical axis. It is supported

to the jacking gears, which you can use to

at its upper end by a roller bearing and at its lower

manually jack the engine over for maintenance.

end by a duplex ball bearing. The lower end is

The "plug-in" gear concept is used on all

also splined to mate with the radial drive shaft.

accessory adapters and idler gears in the aft

section. This concept permits an entire gear,

RADIAL DRIVE SHAFT.--The radial drive

bearing, seal, and adapter assembly to be removed

shaft, a hollow shaft externally splined on each

and replaced without disassembling the gearbox.

end, mates with the bevel gears in the inlet and

Each spur gear is supported by a casing-mounted

transfer gearboxes. Its function is to transmit

roller bearing on one end and an adapter-mounted

power from the inlet gearbox to the forward

ball bearing on the other end. The accessory drive

section (bevel gearbox) of the TGB. The shaft con-

spur gears are internally splined. Internal tubes

tains a shear section (for overtorque protection)

and oil nozzles provide lubrication of the gears

to prevent damage to the accessory drive system.

and bearings. Gearbox carbon-face seals are

retained from the outside of the gearbox. You can

POWER TURBINE/LOW-PRESSURE

replace them without disassembly of the gearbox.

SECTION

The TGB is assembled as a single unit and bolted

to the engine externally. This feature allows you

The PT is used to extract the remaining energy

to replace the entire unit without removing the

from the hot gas. This energy is used to power

engine from the enclosure.

the ship for propulsion. The PT section (fig. 2-37)

has a six-stage LP turbine rotor, a turbine stator,

INLET GEAR BOX.--The inlet gearbox

and a rear frame. The PT is a separate unit from

assembly (fig. 2-36) has a cast aluminum casing,

Figure 2-37.--LM2500 GTE power turbine.

Figure 2-36.--Inlet gearbox.

2-30