support, the stage 1 and stage 2 turbine shrouds,

and the interstage seal. The nozzle support

is a conical section with a flange that is

bolted between the flanges of the compressor

rear frame and the turbine mid frame. The

support provides for the mounting of the nozzles,

the cooling air feeder tubes, and the stage 1

and stage 2 turbine shrouds. The nozzles are

cast and then coated to improve erosion and

oxidation resistance. The vanes (two per nozzle)

direct the gas stream onto the second-stage

turbine blades. The inner ends of the nozzles

form a mounting circle for the interstage seal

attachment. The turbine shrouds form a portion

of the outer aerodynamic flow path through the

turbine. They are located radially in line with

the turbine blades and form a pressure seal

to prevent excessive gas leakage over the blade

tips. The first stage has 24 shroud segments; the

second stage has 11 shroud segments. The inter-

stage seal is composed of six segments bolted to

the nozzles. Its purpose is to minimize gas leakage

between the second-stage nozzle and the turbine

rotor. The sealing surface is honeycomb and has

four steps for maximum sealing. Since the

honeycomb cools more rapidly than the four

rotating sealing teeth, the honeycomb is pre-

grooved to prevent contact under rapid or

emergency shutdown conditions. The second-

stage nozzle is air-cooled by convection. The

nozzle vane center area and leading edge are

cooled by 13th-stage air which enters through

cooling air tubes. Some of the air is discharged

through holes in the trailing edge; the remainder

flows out through the bottom of the vanes and

is used to cool the interstage seals and turbine

blade shanks.

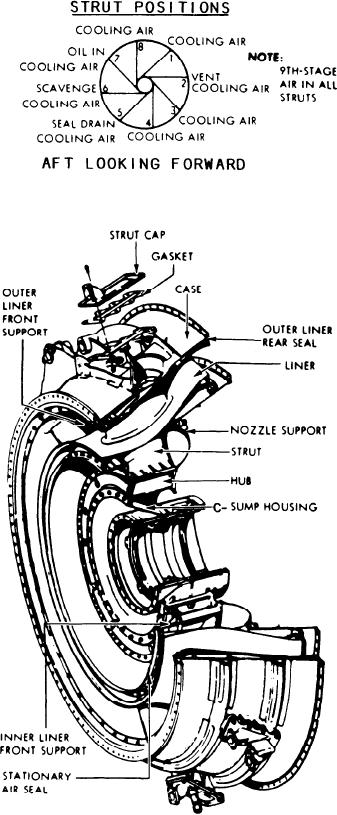

MID FRAME.--The turbine mid frame

(fig. 2-34) supports two areas. It supports the aft

end of the HP turbine rotor (No. 5 bearing); and

the forward end of the PT rotor (No. 6 bearing).

It is bolted between the aft flange of the

compressor rear frame and the forward flange of

the PT stator. The frame provides smooth

diffuser flow passage for HP turbine exhaust gas

into the PT. The frame hub is an open, drum-

shaped, one-piece casting with flanges to support

Figure 2-34.--Turbine mid frame.

the C-sump housing, stationary seals, inner liner

support, and PT first-stage nozzle support. The

The frame has ports for the HP turbine

C sump contains the No. 5 and No. 6 bearings.

exhaust thermocouples and pressure probes (not

Eight struts connect the hub to the outer case. The

shown). These ports also provide access for

struts provide passage for C-sump lubrication and

borescope inspection of the PT inlet area. The PT

scavenge oil, cooling air, sump vent, and seal

first-stage nozzle assembly is part of the frame.

drain services.

2-28