The turbine nozzles are contained in and

supported by the compressor rear frame. The

turbine mid frame, besides supporting the aft end

of the turbine rotor, also supports the front end

of the PT and contains the transition duct. The

gas flows throughout this duct from the HP

turbine section into the PT.

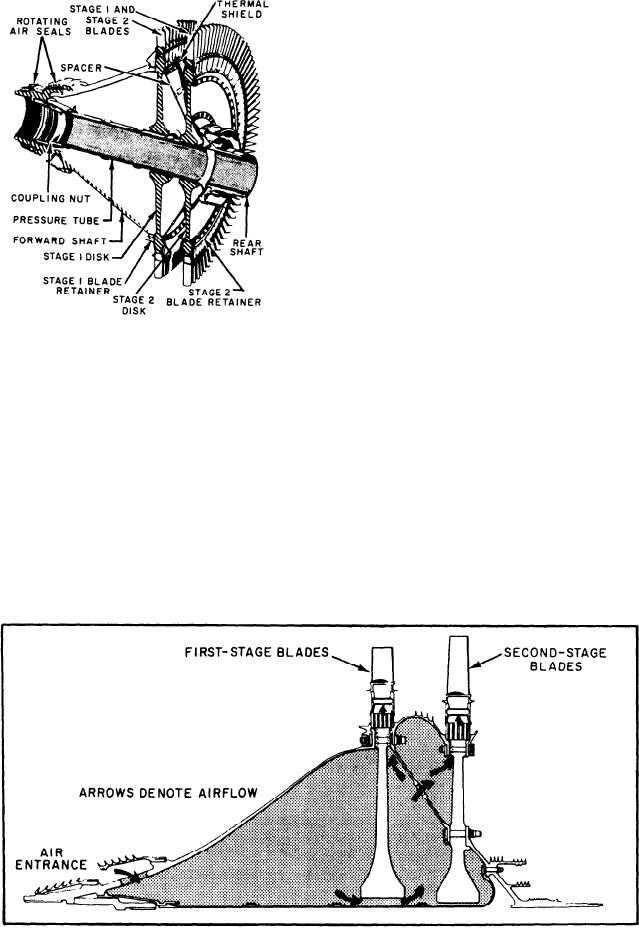

ROTOR.--The HP turbine rotor (fig. 2-29)

has a conical forward shaft, two disks with blades

and retainers, a conical rotor spacer, a thermal

shield, and a rear shaft. The front end of the

turbine rotor is supported at the compressor rotor

rear shaft by the No. 4 bearings. The rear of the

rotor is supported by the No. 5 bearing in the

turbine mid frame (C sump).

Energy extracted from the hot combustion

gases is transmitted to the compressor rotor

through the turbine rotor forward shaft. Two air

seals are on the forward end of the forward shaft.

The front seal helps prevent CDP air from enter-

Figure 2-29.--HP turbine rotor.

ing the sump. The other seal maintains CDP in

the plenum formed by the rotor and combustor.

This plenum is a balance chamber that provides

High-Pressure Turbine Section

a corrective force that minimizes the thrust load

on the No. 4B bearing.

The HP turbine section (fig. 2-28) has an HP

turbine rotor, the first- and second-stage turbine

High-Pressure Turbine Rotor Cooling.--The

nozzle assemblies, and the turbine mid frame. The

HP turbine rotor is cooled by a continuous flow of

turbine rotor extracts energy from the gas stream

compressor discharge air. This air passes through

holes in the first-stage nozzle support and in the

to drive the compressor rotor. The turbine rotor

forward turbine shaft. The air cools the inside of

is mechanically coupled with the compressor

rotor. The turbine nozzles direct the hot gas from

the rotor and both disks before passing between the

the combustor onto the rotor blades at the best

dovetails and out to the blades. Figure 2-30 shows

angle and velocity.

the airflow path for HP turbine rotor cooling.

Figure 2-30.--HP turbine rotor cooling.

2-25