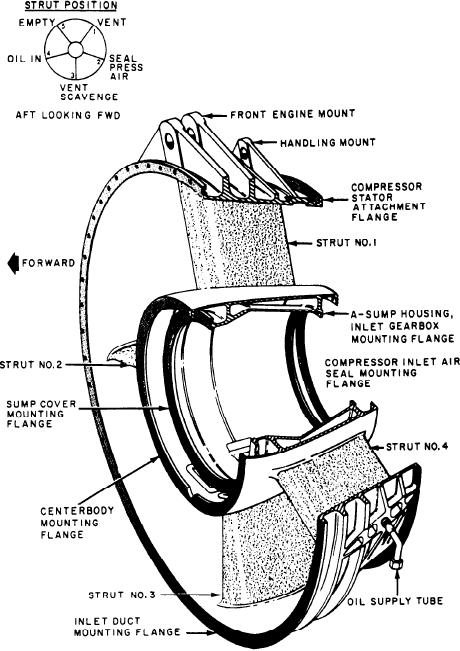

Figure 2-23.--Compressor front frame.

inlet guide vanes (IGVs) and first six stages of

components are the compressor front frame, a

stator vanes are variable; their angular position

compressor stator, a compressor rotor, and the

is varied as a function of GG speed and

compressor rear frame. The primary purpose of

compressor inlet temperature (CIT) by hydraulic

the compressor section is to compress air for

fuel pressure from the main fuel control

combustion. A secondary purpose of the

(MFC). This provides stall-free operation of the

compressor section is to provide air for engine

compressor throughout a wide range of speed and

cooling, sump seal pressurization, and bleed air

inlet temperature. Because these blades are able

for ship's service use.

to be set at different angles, the term variable

Air is drawn in through the front frame. Then

geometry applies to this compressor.

it passes through successive stages of compressor

rotor blades and compressor stator vanes. The air

FRONT FRAME.--The compressor front

is compressed as it passes from stage to stage.

frame (fig. 2-23) provides the forward attachment

After passing through 16 stages, the air has been

point for the GTE, supports the forward end of

compressed in the ratio of about 16 to 1. The

2-20