The screen will also prevent items from

entering the engine if the blow-in doors open.

After major work, major intake cleaning, or

anytime the ship is coming out of a shipyard

environment, a special screen is used. It is a nylon

screen that attaches over the metal FOD screen.

The nylon screen will catch particles much smaller

than the metal screen will. You must be careful

not to exceed specified throttle limitations

when using the nylon screen. Exceeding throttle

limitations could starve the engine for air and

cause a compressor stall. NAVSEA issues specific

instructions for use of the nylon FOD screen.

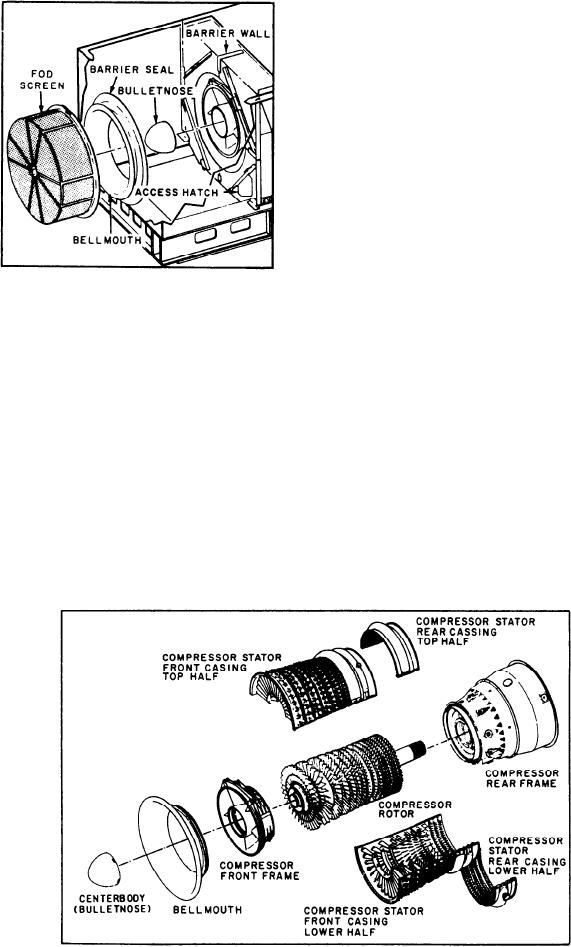

Bellmouth and Bulletnose

The bellmouth and bulletnose (centerbody)

(see fig. 2-21) are mounted on the forward end

of the compressor front frame. These components

Figure 2-21.--LM2500 GTE inlet (FOD screen, centerbody

are used to direct air from the inlet plenum to the

(bulletnose), and bellmouth).

compressor. The surfaces of the two components

have a smooth coat to reduce the turbulence of

FOD Screen

the airflow into the engine. The bellmouth also

contains the water wash manifold. The water wash

The FOD screen, or air inlet screen (fig. 2-21),

manifold is used to inject fresh water and/or a

is mounted on the module barrier wall. The

cleaning solution into the engine. This is done

purpose of this screen is to prevent foreign

when the engine is being motored. This procedure

objects larger than 1/4 inch from entering the

is for maintenance purposes to clean deposits

engine.

from the compressor. The water wash manifold

is supplied by a common water wash system piped

as a ship's system.

The LM2500 GTE compressor (fig. 2-22) is a

16-stage, HP ratio, axial-flow design. Major

Figure 2-22.--LM2500 GTE compressor components.

2-19