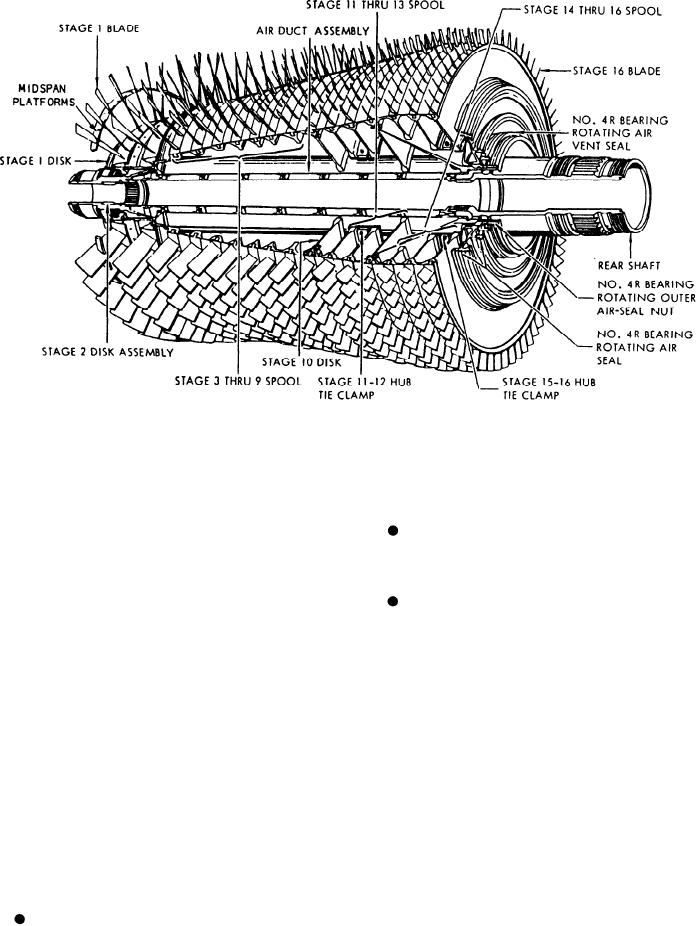

Figure 2-24.--Compressor rotor.

the compressor section, and forms a flow path

9-spool stage are joined by a single bolted joint

for compressor inlet air. Five struts (see strut

at stage 2.

positions, fig. 2-23) between the hub and the outer

case provide passages for lube oil, scavenge oil,

The 3- through 9-spool stage, the stage

seal pressurization air, and a vent for the A-sump

10 disk, and the 11- through 13-spool stage are

components. The bearings of the engine are

bolted at the stage 10 joint.

numbered 3 through 7. The No. 3 bearing, which

The 11- through 13-spool (with its integral

supports the forward end of the compressor rotor

and the inlet gearbox, are located in the A sump.

rear shaft) and the cantilevered 14- through

16-spool connect in a single bolted joint at stage

and CIT sensor (not shown) are mounted in the

13.

outer case. The No. 3 strut (6 o'clock position)

houses the radial drive shaft which transfers

An air duct, supported by the front and rear

shafts, routes stage 8 air aft through the center

power from the inlet gearbox to the transfer

gearbox (TGB) mounted on the bottom of the

of the rotor for pressurization of the B-sump seals.

frame.

Close vane-to-rotor spool and blade-to-stator

casing clearances are obtained with metal spray-

ROTOR. --The compressor rotor (fig. 2-24)

rub coating. Thin squealer tips on the blades and

vanes contact the sprayed material and abrasive

is a spool/disk structure with circumferential

action on the tips prevents excessive rub while

dovetails. The use of spools makes it possible

for several stages of blades to be carried on a

obtaining minimum clearance. The first-stage

blades have midspan platforms to reduce blade

single piece of rotor structure. The seven major

tip vibration.

structural elements and three main bolted joints

are as follows:

STATOR.--The compressor stator has four

The first-stage disk, the second-stage disk

sections bolted together. The top and bottom

cases are manufactured in matched sets. For

(with integral front stub shaft), and the 3- through

2-21