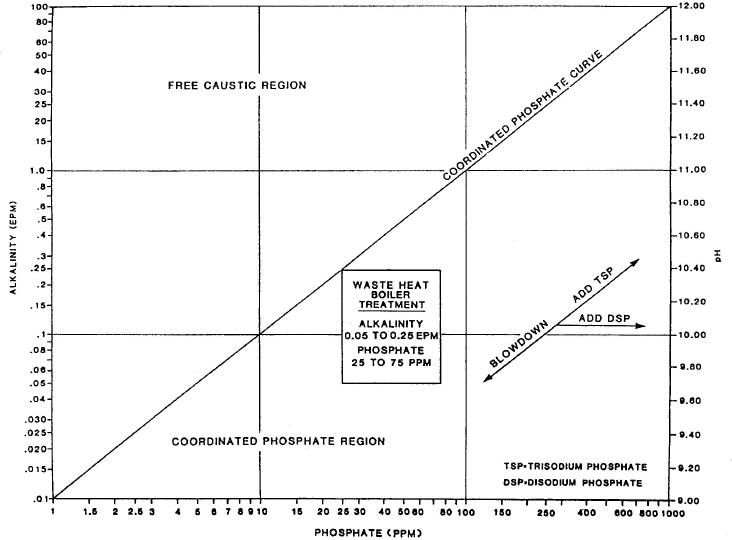

Figure 2-11.--Coordinated phosphate curve (waste heat boilers).

plan. In the following paragraphs, we will discuss

2. Periodically check the dates of the chemicals

how to control contamination under normal and

you have in stock.

abnormal situations. We will also describe some key

symptoms and factors you must be able to interpret

3. Dispose of the outdated stock and rotate the

so you can determine what type of contamination has

rest to get optimum use of the good stock.

occurred.

Another precaution you should take is to test your

CONTAMINATION CONTROL

samples within a reasonable amount of time. Do not

allow your samples to sit for long periods of time

To monitor your ship's water for contaminants,

before you test them.

you must first be able to recognize the standards for

normal operating conditions for both the boiler water

Chloride Test.-- The chloride test will be the last

and the feedwater systems. Next, you must be able to

test you will perform. Although this test is not

recognize when contaminant levels start to exceed

difficult to perform, you must take care to avoid two

normal control limits and threaten to become a

things: (1) adding reagents too quickly during

hazard to your ship's engineering equipment and

titration and (2) attempting to test discolored water.

systems. First, let's talk about the contamination

Adding the reagents too quickly will cause a high

control procedures you will use for boiler water.

chloride reading. Many of the color changes in this

test are very subtle. If you are not careful, you may

Boiler Water

add too much reagent before you notice the color

change.

In monitoring and maintaining the quality of your

ship's boiler water, you will follow routine procedures

Now that the testing is complete, we need to know

how to interpret our results and develop a treatment