the boiler water sample contains sediment. In this case,

deterioration of the piping. As long as only one boiler is

the time between blowdowns should not exceed 24

steaming, the effects of chemical carryover on the boiler

hours. You will not have to secure a waste heat boiler

water chemistry will be minimal. This is because most

before you perform a bottom blowdown.

of chemicals leaving the boiler will be washed to the

feedwater tank and then returned to the boiler. In this

If you follow the procedures for separator or surface

case, it will be easy for you to recognize excessive

blowdowns, you can reduce the alkalinity, phosphate,

carryover by the entries in the boiler water logs. When

conductivity, and chloride of a steaming boiler by about

two boilers are steaming, however, an increase in the

10 percent. If you need more than a 10 percent reduction,

chemical levels can occur in one boiler while a loss of

repeat the blowdown cycles as necessary. Wait 1 minute

chemicals can occur in the other. This is an indication of

between blowdown cycles to allow the water to

carryover. The problem is complicated by the fact that

circulate.

each of the boilers may carry over at different rates.

When a different set of boilers is steaming, the boiler

that was losing chemicals may start gaining them.

CAUTION

Excessive carryover will cause the salinity/conductivity

indicators to read higher than normal for the chemical

chloride test. Another sign of carryover is any detection

Do not blow down a steaming boiler more

of alkalinity in the condensate or feedwater (feedwater

than 50 percent at one time. This time period

sample pink to phenolphthalein).

equates to five 3-inch blowdowns on the

You will need to use specific treatment procedures

CONSECO or 5 minutes on the CE. If you

designed to compensate for chemical carryover. The

overlook these precautions, an excessive

batch dosage will not increase the alkalinity or the

chemical loss occurs. Sample and test as

phosphate to the upper limits to allow for some increase

needed, and base further actions on the test

in the chemicals. The low treatment levels reduce the

results.

amount of chemicals that leave a boiler having excessive

carryover. When you discover that one boiler carries

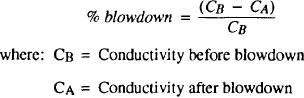

You are required to record the percentage of

over more than another, secure the continuous treatment

blowdown on a steaming boiler in the boiler water

system to the boiler that is collecting the chemicals.

treatment log. To determine the percentage of

Adjust the continuous treatment to the boiler that is

blowdown, use the following formula:

carrying over to maintain the chemical levels as low as

possible. Excessive carryover may cause the indicator

alarms to activate. If this happens, just bypass the alarm.

When contamination occurs, the boiler water chloride

will carry over and cause high chloride test results in the

feedwater. To reduce the contamination, it is more

effective to blow down the boiler than to dump the

feedwater. If the carryover is so severe that it is

Remember, the conductivity is proportional to the

impossible to maintain the water chemistry, a problem

concentration of all of the dissolved solids present in the

with the steam separator may be indicated.

b o i l e r water from treatment chemicals and

Slowdowns.--

Once you have identified

contaminants. The conductivity will remain within

contaminants and additional chemicals in boiler water,

limits as long as the other test results are within the

how do you remove them? To remove the contaminates

proper ranges.

and excess chemicals, you must blow down the boiler.

The chloride level will provide you with an

You must use either a separator blowdown for

overview of the level of contamination entering the

CONSECO boilers or a surface blowdown for

boiler. You can maintain an acceptable chloride level of

combustion engineering (CE) boilers. You must use

less than 1.0 epm by maintaining good distillate quality

either a separator or surface blowdown any time your

and correcting any in-leakage of seawater or potable

test results indicate the need. You must also perform

water.

periodic bottom blowdowns to control sludge buildup.

You do these weekly, or as needed, to make sure the time

Now that we have discussed the testing and

between blowdowns does not exceed 168 steaming

treatment of boiler water, let's talk about where the

hours. You must perform a bottom blowdown daily if

boiler water comes fromthe feedwater.