important thing you can do is to use the correct

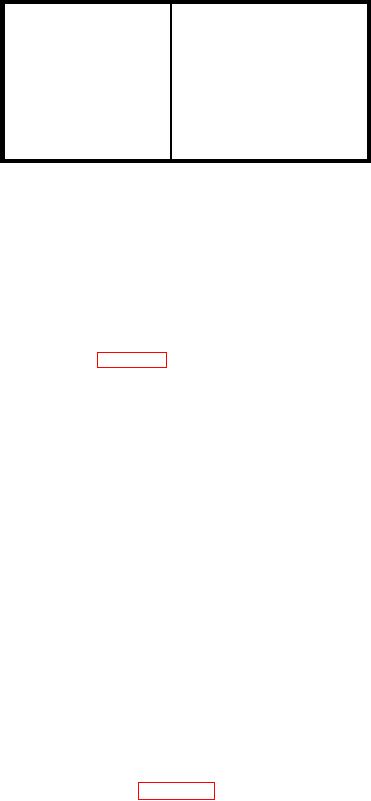

Table 2-2.--Waste Heat Boiler Control Limits

procedures. In testing and treating boiler water, you

will use a different set of procedures for different

parts of the boiler water system. When testing for

Alkalinity

0.05 to 0.25 epm

chloride and conductivity, for example, you must use

the procedures for propulsion boilers. When testing

Phosphate

25 to 75 ppm

for alkalinity and phosphates, you must use the

procedures for auxiliary boilers. Both procedures are

Conductivity

500 mho/cm maximum

explained in detail in NSTM, chapter 220, volume 2,

"Boiler Water/Feedwater Test and Treatment." In

Chloride

1.0 epm maximum

routine testing you will actually be shifting from one

procedure to the other. The reason for this is based on

the natural order in which you should perform the

procedures according to the type of water you will be

testing. For a detailed description of all procedures,

testing.

we recommend you consult NSTM, chapter 220,

volume 2. At first this process maybe confusing, but

Boiler Water

the more familiar you become with this NSTM

chapter, the easier these procedures will become. We

The boiler water testing and treatment procedures

will explain the highlights of both tests in the

you will use are based on the coordinated phosphate

following paragraphs.

program. The Navy uses this program to prevent acid

corrosion, caustic corrosion, and scale formation in

Boiler Water Conductivity Test.-- Let's go to

boiler water. Table 2-2 contains the Navy's standard

boiler water control limits. If you study this table

the propulsion boiler section for the boiler water

carefully, you will see what compounds you will test

conductivity test. Because it is easy to perform and

for and their acceptable concentration limits.

does not require much time, this test should be done

first. (It should also be done first because the test

CHEMICALS.-- The first thing you need to learn

results can be affected by the absorption of CO2.)

about boiler water testing is the treatment chemicals

you will use and how these chemicals work to control

To perform this test, you will use the conductivity

the contaminants you are monitoring. Trisodium

meter, a dip-type conductivity cell (2.0 cell constant),

phosphate (TSP) and disodium phosphate (DSP) are

a thermometer, an 8-ounce square bottle, and

the chemicals you will use to treat the waste heat

distilled water. As easy as this test procedure is,

tiller water. TSP provides alkalinity and some of the

there are still two important steps that are sometimes

phosphate. DSP provides additional phosphate while

overlooked: (1) You must move the cell up and down

contributing little to the alkalinity. Maintaining

in the bottle to remove trapped air bubbles, and (2)

alkaline boiler water prevents acid corrosion and

you must move the cell up and down in the bottle

provides the necessary environment for the

during the measuring phase until the movement no

phosphate to react with the scale formers. The

longer affects the meter readings. Keeping the cell

additional phosphate prevents the formation of free

clean is another important task that is sometimes

caustic in the boiler water, an undesirable condition

overlooked. The most common mistake, however, is

that could lead to caustic corrosion. The propulsion

forgetting to change the distilled water in the cell

boilers measure the pH of the boiler water rather

storage bottle on a daily basis. For accurate results,

than the alkalinity. The corresponding pH range is

you must make sure the distilled water in the storage

about 9.7 to 10.4. The relationship of the waste heat

bottle containing the cell is changed daily.

boiler water treatment to the coordinated phosphate

curve is shown in figure 2-11.

Alkalinity and Phosphates Test.-- A common

mistake in boiler water testing is the use of outdated

In the next few paragraphs, we will discuss some

test chemicals. Before you perform the alkalinity and

of the highlights of the boiler water testing

phosphates test, you should check your test chemicals

procedures you will use. We will also warn you about

to make certain they are still active. To do this, check

some of the mistakes that are commonly made during

the dates on the containers to make certain the

the performance of these procedures.

chemicals are not outdated. You can avoid using

outdated chemicals by taking the following steps:

PROCEDURES.-- Accurate test results are

essential for an effective boiler water treatment

1. Do not overorder your test chemicals.

program. To get accurate test results, the most