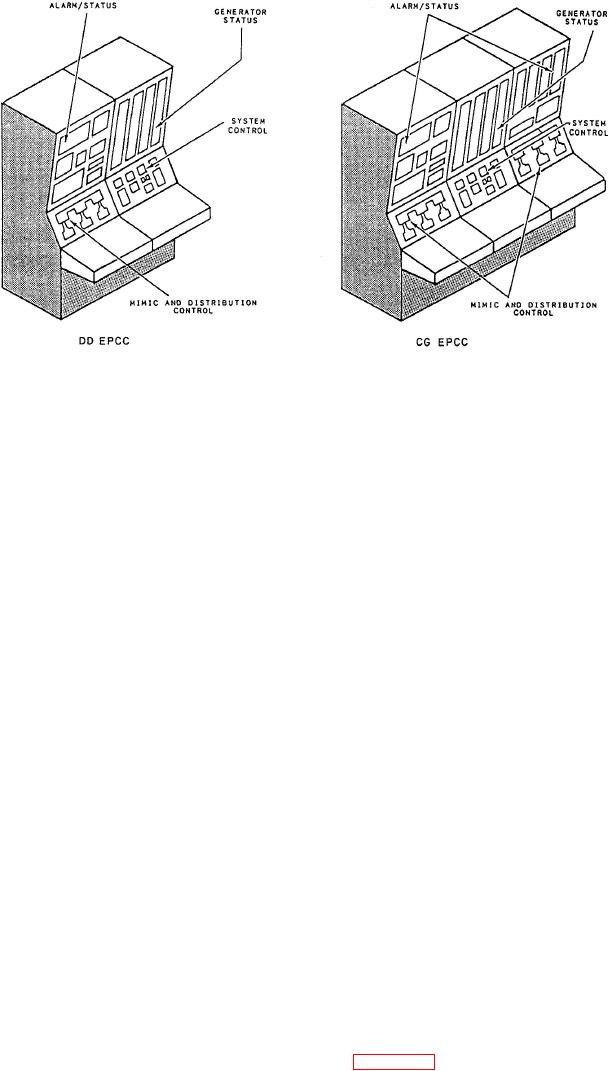

Figure 3-3.--EPCC layout.

As long as these systems are in AUTO and the

6. Distilling plant

propulsion plant is in one of the three propulsion

configurations (either secure, split plant, or full power),

7. Air-conditioning (A/C) plant

the plant mode system control is enabled. With plant

mode control enabled, the operator can perform the

8. High-pressure air system

following mode changes at the PACC:

9. Ship's service air system

1. Secure to split plant (CG-47 class ships only)

10. Chilled-water expansion tank system (CG-47

2. Split plant to full power

class only)

3. Full power to split plant

11. Combat dry-air system (CG-47 class only)

4. Full power or split plant top secure

12. AEGIS pump system (CG-47 class only)

5. Change engine

You have just read about the eight control systems

available at the PACC in DD-963, DDG-993, and CG-

Now let's shift from the plant mode control system

47 class ships. Now, let's take a look at the control

to the remaining system that can be controlled at the

systems at the EPCC for these ships.

PACC, the auxiliaries.

EPCC

Auxiliaries Systems

The electric plant control systems monitor and

There are certain engineering plant auxiliaries that

control the performance and operation of the

can be both monitored and controlled by the ECSS.

equipment associated with the ship's electrical

There are other auxiliaries that can only be monitored.

systems. The EPCC contains the controls and

The following list contains the auxiliaries that can be

indicators that are used for remote operation and

either monitored or controlled at the PACC:

monitoring of the ship's service power generation and

distribution systems. Remotely produced commands

1. Waste heat boiler (WHB) (emergency stop only)

from the EPCC operate controls to sequence the

operation of equipment or control subsystem operation.

2. Seawater service (start/stop)

In fact, the operation of the equipment associated with

the electrical distribution systems is normally

3. Freshwater service (start/stop)

controlled from the EPCC.

4. Refrigeration plant

Figure 3-3 shows a typical layout of an EPCC.

Notice how each panel is dedicated to particular types

5. Sewage and waste system 6.