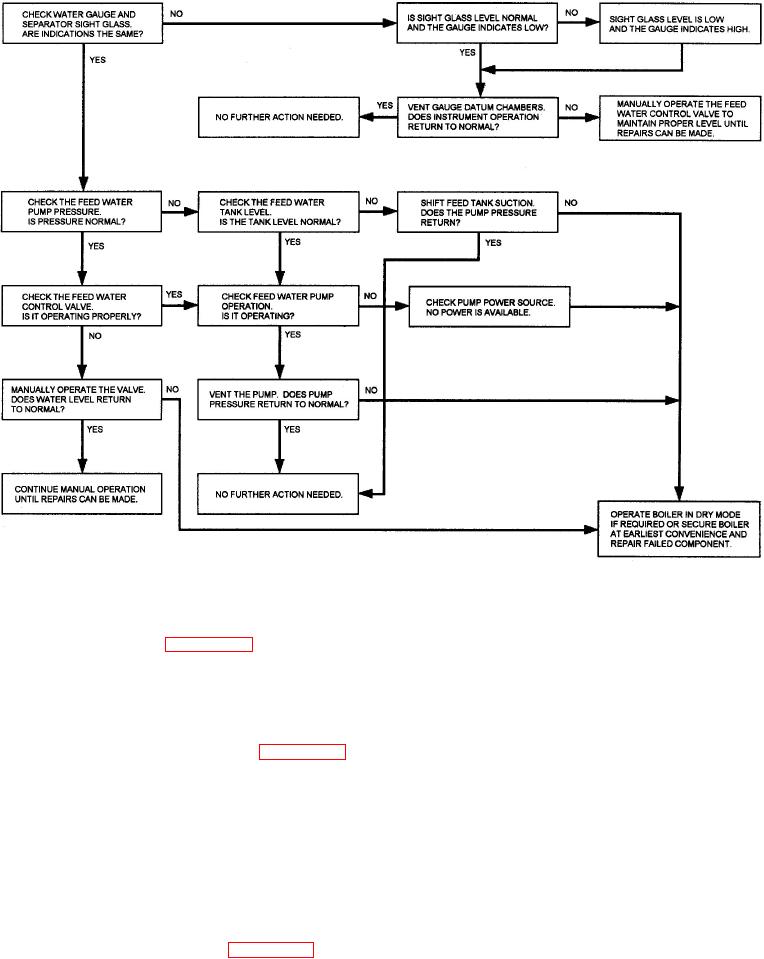

Figure 4-10.-Troubleshooting chart for low boiler water.

2. Faulty diverting valve - If this valve fails open

troubleshooting chart in figure 4-10 explains some

or the pneumatic pilot valve malfunctions, most of the

key items you can check to help pinpoint the source of

steam pressure will be diverted back to the

the problem.

condensate system. Remember, this valve has manual

NOTE

override capabilities.

3. Faulty or airbound recirculating pump - If the

The troubleshooting chart shown in figure 4-10

recirculating pump stops operating, no water can be

contains general information only and should

moved from the separator to the boiler coils. Also, if

not take the place of the EOSS or approved

the pump becomes airbound, you should try to vent

manufacturer's technical guide.

the pump casing to restore water flow. Remember, if

either of these two problems cannot be resolved

Maintaining the Proper Steam Pressure. The

quickly, the boiler will run dry. A quick way to

second most common problem that we will discuss is

determine if the boiler tubes are dry is to watch the

maintaining a proper steam pressure. The following

inlet and outlet exhaust gas temperatures. The closer

list contains the components or conditions that are

or more equal they are, the more likely the boiler is

most likely to cause this problem:

approaching or is already in dry operation.

1. Low boiler water - Review figure 4-10 of this

MAINTENANCE. In this section, we will discuss

chapter and the procedures in the EOSS or approved

some of the maintenance you as a GSM will either be

technical manuals.

required to perform or expected to know. We will only