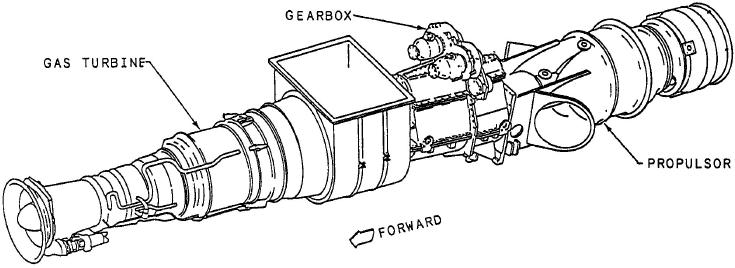

Figure 6-21.-Foilborne propulsion system.

exhaust duct through primary and secondary eductor

occurs as seawater is pumped through the water jets

nozzles, which create a flow of secondary cooling air

and expelled through a nozzle at the stem. The

through the gas turbine machinery room. Located in

reactive force resulting from the acceleration and

the aft end of the gas turbine machinery room is the

expulsion of the seawater drives the ship forward.

foilborne engine exhaust collector. When the GTE is

The main advantage of this system is its speed and

running, the exhaust works like an eductor to draw

efficiency in driving the craft forward. When

cooling air into this compartment from ventilation

foilborne, the PHM can attain speeds greater than 40

ducts through the auxiliary machinery room No. 1.

knots. A disadvantage, however, is that there is no

When the GTE is secured, fans on either side of the

provision for reversing the craft when the PHM is in

combination air inlet furnish cooling air for the

the foilborne mode.

engine and its compartment. The exhaust gases

eventually exit through the foilborne engine exhaust

The basic foilborne propulsion system consists of

stack located just aft of the superstructure.

the GTE (power plant), a power train assembly, and a

propulsor assembly. In the following sections, we will

In addition to the LM2500 GTE, the gas turbine

examine the main components of the foilborne

machinery room contains other foilborne propulsion

system, starting with its power plant, the LM2500

system equipment, including the foilborne engine

GTE.

lube oil supply and return filters, engine lube oil-to-

fuel heat exchanger, engine fuel heater, propulsor

LM2500 GTE ASSEMBLY

gearbox lube oil-to-engine fuel heat exchanger for

operating in cold areas, and propulsor gear lube oil-

The power for the foilborne system is provided by

to-engine lube oil heat exchanger for operating in hot

a General Electric LM2500 GTE located in the gas

areas.

turbine machinery room. This GTE is the same type

that is used in the twin-shaft and single-shaft ships.

Lube Oil System

The gas turbine assembly consists of a gas generator,

a power turbine, a high-speed coupling shaft, and an

The LM2500 GTE lube oil system provides two

exhaust duct. At 100 percent power, this GTE is

main functions: (1) it supplies cool oil to the gas

capable of delivering 16,767 hp to the gearbox

assembly at about 3,100 rpm.

excessive friction and heat, and (2) it supplies heat

through the oil-to-fuel heat exchanger to heat the fuel

The LM2500 GTE draws combustion air through

for the gas turbine. The lube oil is stored in a 7.2-

knit-mesh filters located on the weather deck. The

gallon oil tank located over the engine. The oil is

combustion air flows through the demister panels and

gravity-fed from the storage tank to the lube and

the air intake plenum, which interfaces with the

scavenge pump mounted on the gas turbine. The

forward end to the gas turbine machinery room. A

single-supply element of the pump forces the lube oil

barrier wall and seal prevent any air from the area

through tubes to the specific areas requiring

surrounding the engine from entering the combustion

lubrication.

air intake. The exhaust gases flow from the GTE