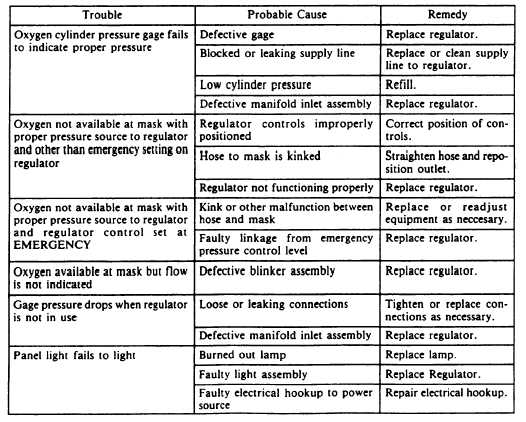

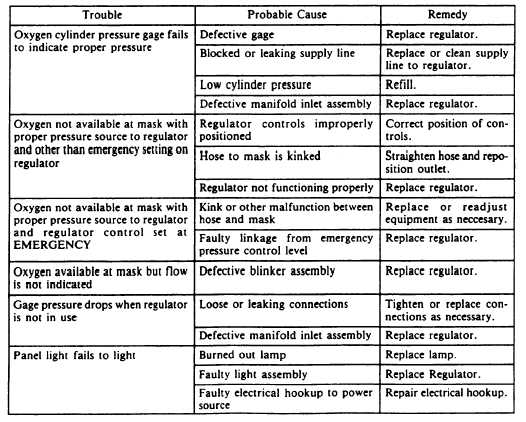

the regulators preinstalled. Refer to table 12-4

for assistance in troubleshooting. To perform the

inspection, visually inspect the following:

1. Electrical performance of panel light.

2. Legibility of all markings.

3. Plastic lighting plate for cracks and

discoloration.

4. Low, or improper reading on regulator

pressure gauge.

5. Emergency pressure control lever in

NORMAL position.

6. Diluter control lever in 100-percent

OXYGEN position.

7. Supply control lever in OFF position.

8. Regulator and surrounding area for

freedom from dirt and hydrocarbons.

9. Delivery hose and connector for cuts,

graying, kinking, hydrocarbons and general

condition.

If discrepancies are found or suspected, notify

maintenance control.

If a regulator does not pass your inspection

and the defect cannot be repaired in the aircraft,

remove it and put in a ready for issue (RFI)

regulator. Forward the defective regulator to an

aircraft intermediate maintenance activity that can

fix it.

ACCEPTANCE/SPECIAL/DAILY

INSPECTIONS

The acceptance/special/daily inspections

consist of a visual inspection followed by

a functional test. These inspections and tests

are performed in conjunction with the air-

craft inspection requirements for the aircraft

in which the regulators are installed. These

inspections are performed at the organizational

level by AMEs. However, you should know

what they are supposed to inspect. Refer to

table 12-4 for assistance in troubleshooting.

To perform the inspection, visually inspect

the regulators as you did in the preflight

inspection.

Table 12-4.-Troublesbooting (Daily, Preflight, Special, Turnaround, Transfer and Acceptance Inspections)

12-8