2. Place the emergency pressure control lever

in the EMERGENCY position.

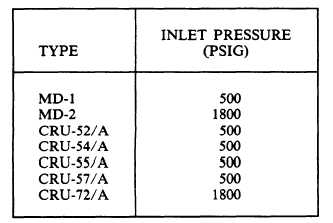

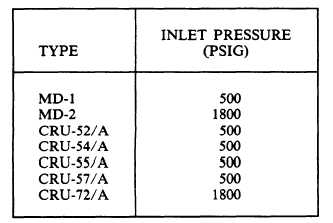

3. Using HIGH PRESSURE REGULATOR,

apply pressure specified in table 12-6 to the

regulator inlet.

Slowly turn the INLET

PRESSURE ON/OFF valve to ON.

4. Draw a film of leak detection compound

(MIL-L-25567) across the regulator outlet fitting.

As in the last test, see if there is any distention

of the film.

5. There is no allowable leakage. If leakage

is noted, locate probable cause using

troubleshooting chart, table 12-7.

6. Place the emergency control lever in the

NORMAL position.

OVERALL LEAKAGE TEST.— Test, by

trapping pressure in the regulator, for any leakage

anywhere on or in the regulator. Perform the

overall leakage test first with diluter lever in its

100-percent OXYGEN position, and then repeat

it with the lever in the NORMAL OXYGEN

position.

1. Place regulator oxygen supply valve lever

in the ON position, and emergency pressure

control lever in the NORMAL position.

2. By using test stand HIGH PRESSURE

REGULATOR, apply pressure specified in table

12-8 to regulator inlet.

3. Turn INLET PRESSURE ON/OFF valve

to OFF. Leave the regulator oxygen supply valve

lever in the ON position.

4. Leakage will be indicated on the regulator

pressure gauge. Allowable leakage should not

exceed 60 psig over a 2-minute period. Repeat the

test with the diluter lever turned to NORMAL

OXYGEN.

Table 12-6.—Inlet Pressure (Oxygen Supply Valve Leakage

Test)

12-12

5. If allowable leakage is exceeded, locate the

probable cause by using the troubleshooting chart,

table 12-9.

6. Turn the HIGH PRESSURE REGULA-

TOR to VENT.

7. Bleed the regulator by placing the emer-

gency pressure control lever in the EMERGENCY

position. Return the lever to NORMAL.

8. Bleed the test stand using the SYSTEM

BLEED valve.

REGUI.ATOR PRESSURE GAUGE SCALE

AND ERROR TEST.— This test ensures that the

pressure gauge is operating properly and within

tolerance. To perform the regulator pressure

gauge scale and error test, proceed as follows:

1. Turn the INLET PRESSURE ON/OFF

valve to ON. The LOW PRESSURE REGULA-

TOR can only be used when applying pressures

below the gauge guard setting (165 to 175 psig)

to an item under test. For pressures above the

gauge guard setting, the HIGH PRESSURE

REGULATOR must be used.

2. Using LOW PRESSURE REGULATOR

(N), slowly increase the pressure to each test

pressure in 100 psig increments and below, as

specified in table 12-6. Record the regulator

pressure gauge readings twice, once before and

once after tapping regulator pressure gauge.

3. Check the tolerance by comparing the

regulator pressure gauge reading with the test

stand INPUT PRESSURE gauge.

4. Back out on the LOW PRESSURE

REGULATOR.

5. Continue the test for 500 psig pressure by

using the HIGH PRESSURE REGULATOR.

6. Turn the HIGH PRESSURE REGULA-

TOR to VENT.

7. Bleed the test standby using the SYSTEM

BLEED valve. Bleed the regulator using the

emergency pressure control lever.

OUTWARD LEAKAGE TEST.— In per-

forming this test, the relief valve is not covered.

The allowable leakage through this valve at 17.0

inches H2O is included in the maximum allowable

leakage of 120 ccm.

NOTE: This text uses the abbreviations

lpm for liters per minute. Newer equipment

and technical manuals may use the correct

abbreviation, which is L/min.