5. Turn the FLOW SELECTOR valve to the

REGULATOR position and close the VENT

AMBIENT valve.

6. Slowly move the PRESSURE SELEC-

TOR valve to the H2O position.

7. Turn the LEAKAGE SELECTOR valve

to the LOW position.

8. Open the LEAKAGE CONTROL valve.

Apply and maintain 17.0 inches of H2O to

regulator outlet. Maximum allowable leakage is

0.12 lpm (120 ccm).

9. Close the LEAKAGE CONTROL valve.

10. Back out on the LOW PRESSURE

REGULATOR and bleed the pressure with the

SYSTEM BLEED valve.

11. Turn the LEAKAGE SELECTOR valve

to the HIGH RANGE position.

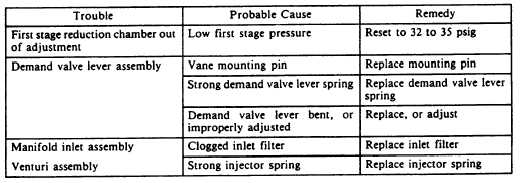

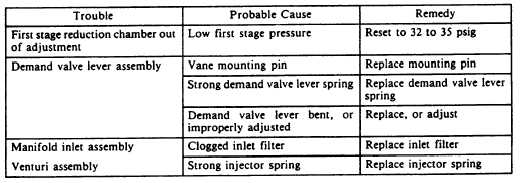

12. If excessive leakage is found, locate the

probable cause using the troubleshooting chart,

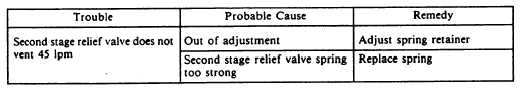

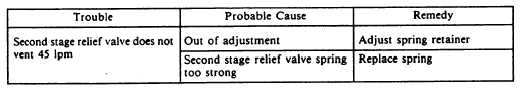

table 12-10. If the relief valve does not vent, locate

the probable cause by using the troubleshooting

chart, table 12-11.

FLOW SUCTION TEST.— This test deter-

mines how much suction will be required by the

user to achieve or receive a given amount of

oxygen or air/oxygen mixture through the

regulator. To perform the flow suction test,

proceed as follows:

1. Disconnect the hose from the LOW

PRESSURE connection and REFERENCE TAP

connection inside the altitude chamber.

2. Turn vacuum pump ON.

3. Ensure that the PRESSURE SELECTOR

Valve is in the H2O position.

4. Ensure that the regulator diluter control

lever is in the 100-percent OXYGEN position.

5. Ensure that the INLET PRESSURE

ON/OFF valve is ON.

6. Ensure that the regulator supply valve

control lever is in the ON position.

7. By using the LOW PRESSURE REGU-

LATOR, set the inlet pressure at each inlet pres-

sure specified on the Performance Test Sheet.

8. By using the OUTPUT valve, set flows

specified in the Performance Test Sheet on

the OUTPUT manometer. Readings must be

recorded with the regulator diluter control lever

in both NORMAL and 100-percent OXYGEN

positions for each outlet flow specified on the

Performance Test Sheet. Suction values will be

displayed on PRESSURE/SUCTION manome-

ter. With no suction on the regulator (OUTPUT

valve closed), maximum flow through regulator

should not exceed 0.01 lpm. This will cause a

slight rise in the PRESSURE/SUCTION ma-

nometer reading.

Record readings on the

Performance Test Sheet.

9. Close OUTPUT valve.

10. If the regulator fails the flow suction test,

locate the probable cause by using the

troubleshooting chart in table 12-12.

Table 12-11.—Troubleshootig (Second Stage Relief Valve Test)

Table 12-12.—Troubleshooting (Flow Suction Test)

12-15