4. Place the emergency control lever in the

EMERGENCY position. Pressure indicated on

PRESSURE/SUCTION manometer should read

2.0 to 4.0 inches of H2O.

5. Adjust the OUTPUT valve to draw 80

lpm through the regulator.

6. Place the diluter control lever in the

100-percent OXYGEN position. Pressure at outlet

of regulator, as indicated on PRESSURE/

SUCTION manometer, should be no less than 1.0

inches of H2O.

7. Close the OUTPUT valve. With zero

flow, outlet pressure should not exceed 5.5 inches

of H2O .

8. Adjust the output to 10 lpm. Hold the

emergency pressure control lever in TEST MASK

position. The output flow indicated on the

PRESSURE/SUCTION manometer should be

6.0 to 16.0 inches of H2O.

9. Close the OUTPUT valve. With zero flow,

outlet pressure should not exceed 17.5 inches of

H2O. Release the emergency pressure control

lever. If the regulator fails, adjust the emergency

pressure control lever stem to obtain 3.0 to 4.0

inches of H2O at 10 lpm first, then compensate

for excessive pressure drop at 80 lpm flow with

the elastic stop nut.

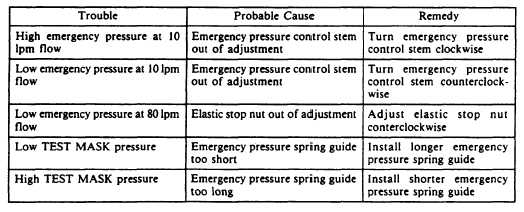

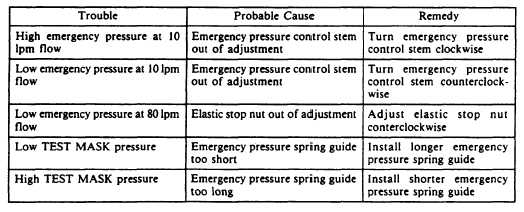

10. If the emergency pressure flows are not

within tolerance, locate the probable cause by

using the troubleshooting chart, table 12-15.

11. Close the N2 supply cylinder valve, by

using the LOW PRESSURE REGULATOR and

SYSTEM BLEED valve, relieve all pressure in the

test stand. Secure all test stand valves.

12. Test stand operator and CDI must sign

the Performance Test Sheet. The original, or a

copy of the Performance Test Sheet is forwarded

to the operational custodian of the regulator.

LIQUID OXYGEN CONVERTERS

The liquid oxygen converter assembly dis-

cussed in this chapter is a GCU-24/A, P/N

10C-0016-10 (fig. 12-5) manufactured by Essex

Cryogenics, Inc. (FSCM 19062). Information

concerning other types can be found in NAVAIR

13-1-6.4. The converter assembly is designed to

store and convert liquid oxygen (LOX) into

gaseous oxygen for the aircrewman during flight.

Table 12-16 contains the leading particulars for

the converter assembly.

Oxygen in its liquid state (approximately

–297 °F or –182 °C) is stored in a spherical

assembly consisting of inner and outer shells

separated by an annular space. The annular space

is evacuated to create a vacuum. This prevents the

transmittal of heat through the annular space. The

thermos bottle effect created retards heating and

eventual conversion of LOX to gaseous oxygen.

Valves, tubing, and fittings incorporated in the

converter assembly convert LOX to gas and direct

its flow at a controlled rate.

CONFIGURATION AND FUNCTION

The type GCU-24/A Liquid Oxygen Con-

verter Assembly (P/N 10C-0016-10) consists of

a sphere assembly, buildup and vent valve, relief

valve, pressure closing valve and associated

tubing and fittings. A capacitance-type probe

assembly, which sends an electrical signal to a

Table 12-15.—Troubleshooting (Emergency Pressure Test)

12-18