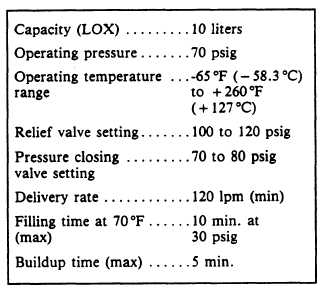

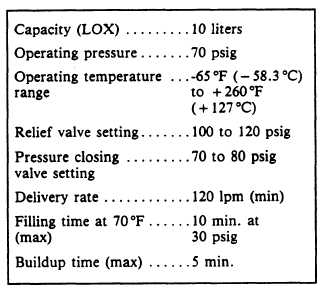

Table 12-16.—Leading Particulars for Liquid Oxygen Con-

verter Assembly, Type GCU-24/A, P/N 10C-0016-10

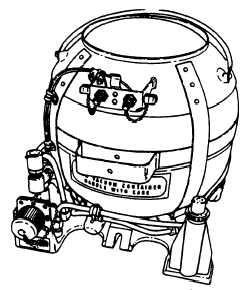

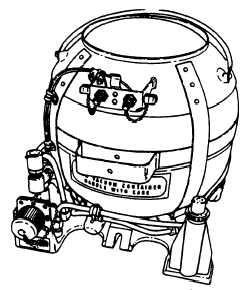

Figure 12-5.—Liquid oxygen

GCU-24/A, P/N

converter assembly, type

1OC-OO16-1O.

liquid oxygen quantity gauge located in the air-

craft, is incorporated within the sphere assembly.

The quantity gauge indicates the amount of LOX,

in liters, contained in the converter.

Operation and performance characteristics of

the GCU-24/A converter assembly (P/N

10C-0016-10) are as follows:

1. The converter is filled by attaching the

LOX servicing trailer filler valve to the filler port

of the fill, buildup, and vent valve on the

converter. When attached, the servicing trailer

filler valve depresses the nosepiece and valve

poppet of the fill, buildup, and vent valve. This

automatically puts the converter into the fill mode

(fig. 12-6). Figure 12-7 shows the converter

installed in an aircraft.

2. With the poppet depressed, the fill and vent

ports of the valve are opened, and the buildup

port is closed. This condition allows gas pressure

built up in the inner sphere to vent to the

atmosphere. As pressure is vented, LOX in the

servicing trailer (which is at a greater pressure-30

psig), flows through the fill, buildup, and vent

valve and into the converter.

3. As the LOX level rises in the sphere,

pressure created by vaporization of liquid due to

heat, turbulence, etc., is vented to the atmosphere.

The converter is considered full when LOX flows

in a steady stream from the overboard vent line

quick disconnect.

4. When the converter is full and the servicing

trailer filler valve is disconnected, the nosepiece

and poppet of the fill, buildup and vent valve

return to the extended position (fig. 12-6). This

automatically puts the converter into the buildup

and supply mode by closing the fill and vent ports

of the vaIve, and opening the buildup port.

5. In the buildup and supply mode (fig. 12-6),

LOX is forced out of the bottom of the inner

sphere and into the buildup coil by the weight of

the liquid. As the LOX warms and vaporizes

into gaseous oxygen in the buildup coil, pressure

is created. This pressure is controlled at

approximately 75 psig by the opening and closing

action of the pressure closing valve.

6. Gaseous oxygen travels from the buildup

coil through the supply quick disconnect and the

heat exchanger to a shut-off valve in the aircraft

cockpit.

7. Gaseous oxygen, under pressure, also

passes through the gas and buildup ports of the

fill, buildup and vent valve to the upper portion

of the pressure closing valve, within which is a

bellows. This bellows holds the valve in the open

position. As pressure builds, the bellows, which

senses the increase, contracts (at approximately

75 psig), and closes the valve.

8. Without a demand being placed on the

converter, pressure continues to slowly rise. If

12-19