11. Disconnect the line from the LOW

PRESSURE connection and REF. TAP in the

altitude chamber. Disconnect the regulator outlet

from N2 INPUT connection, and remove the plug

from the piezometer.

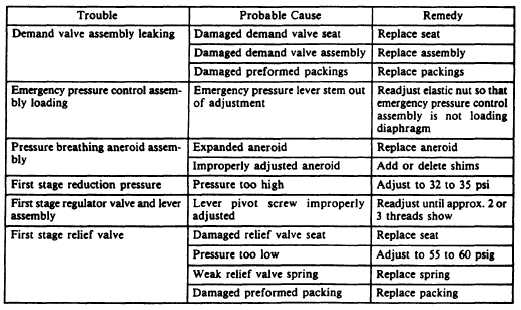

12. If excessive leakage is indicated, locate the

probable cause by using troubleshooting chart,

table 12-5A.

Outlet Leakage Test

To perform an outlet leakage test, proceed as

follows:

1. Place the regulator supply valve control

lever in the ON position.

2. Ensure that the diluter control lever is in

the 100-percent OXYGEN position.

3. Place the emergency pressure control lever

in the NORMAL position.

4. Mount the regulator on a horizontal plane

in the test chamber. Connect the regulator inlet

to the N2 INPUT connection (18) inside the

altitude chamber.

5. By using the LOW PRESSURE REG-

ULATOR, apply 150 psig to the regulator inlet.

6. Slowly turn the INLET PRESSURE

ON/OFF valve to ON.

7. Activate the emergency pressure control

lever to allow a flow through the regulator, then

return the lever to its NORMAL position.

8. Draw a film of leak detection compound

(MIL-L-25567) across the regulator outlet. The

film should not advance more than 1/2 inch in

10 seconds. If the film advance is more than

allowable, repeat the test three or four times.

(Distention could be caused by difference in

temperature between inside and outside of

regulator.)

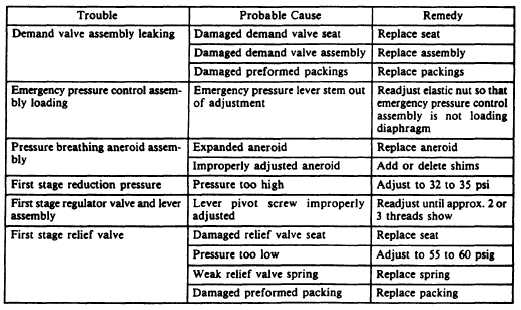

9. If the film advance continues to be more

than allowed, locate the probable cause by using

the troubleshooting chart, table 12-5B.

10. Relieve pressure on the regulator by back-

ing out on the LOW PRESSURE REGULATOR.

OXYGEN SUPPLY VALVE LEAKAGE

TEST.— If the supply pressure could not be shut

off, until a demand was placed on it, a pressure

buildup could be created. It could damage the

regulator hose or mask and possibly injure the

crewmen. To perform the oxygen supply valve

leakage test with the regulator still mounted in the

chamber, proceed as follows:

1. Place the regulator oxygen supply valve

lever in the OFF position.

Table 12-5B.—Troubleshooting (Outlet Leakage Test)

12-11