15. Ensure that bleed valve V-2 is opened and

all other test stand valves are closed.

16. Measure the force required to disengage

the automatic oxygen release with a scale. This

force should be 10 to 30 pounds when it dis-

engages; the emergency oxygen system should

actuate and indicate 45 to 80 psi on gauge

PG-1.

17. Reset the reducer.

18. Open valve V-5 to bleed pressure.

19. When pressure is bled, as indicated by no

indication on gauges PG-1 and PG-4, close valve

V-5. Now, observe gauge PG-4 for 2 minutes. Any

pressure rise indicates leakage in the valve seat of

the reducer/manifold.

20. Open valve V-5 and close valve V-2.

21. Disconnect the oxygen hose from fitting

C-1.

22. Ensure all valves on the test stand are

secured.

23. Connect the oxygen outlet hose to fitting

NIP-6. Ensure that valve V-10 is open and all

other test stand valves are closed.

24. Connect the test stand hose between

fitting NIP-5 and fitting NIP-4.

25. Move valve V-1 to the NIP-4 position.

26. Ensure that 1,800 to 2,000 psi is in the

oxygen cylinder of the kit.

27. Pull the manual oxygen release. Slowly

open valve V-9 to indicate 90 liters per minute on

gauge PG-2. Oxygen pressure should be indicated

as 45 to 80 psi on gauge PG-1.

28. Observe emergency oxygen cylinder

pressure gauge and allow the system to decrease

to 250 psi while maintaining 90 LPM and 45 to

80 psi pressure. When needle of this cylinder

pressure gauge is between the E and F of REFILL,

pressure is approximately 250 psi.

29. Close valve V-9.

30. With zero flow indicated on gauge PG-2,

gauge PG-1 should indicate 45 to 80 psi.

31. Reinstall the manual oxygen release (if

separating type) and reset the reducer.

32. Bleed the oxygen pressure from the system

by opening valves V-5 and V-2. All pressure is bled

when gauges PG-1 and PG-4 indicate zero

pressure.

33. Disconnect the kit from the test stand.

34. Secure the test stand.

35. Thoroughly clean all areas wetted with

leak test solution with clean water. Dry them with

a lint-free cloth, filtered low-pressure compressed

air, or by low-pressure nitrogen.

36. Recharge the emergency oxygen cylinder

to 1,800 to 2,000 psi.

37. Perform a release handle pull test on the

fully packed kit. (Refer to NAVAIR 13-1-6.3 for

instructions.)

PURGING AND CHARGING

EMERGENCY OXYGEN SYSTEMS

To purge and charge the emergency oxygen

cylinder, proceed as follows:

Materials Required

Leak detection compound

Oxygen purging electric heater

Nitrogen, type I, class I, grade A

Aviator’s breathing oxygen, type I

Shutoff valve

Pressure regulator

Adapter, filling

1. If the survival kit assembly has not been

removed from the aircraft, remove the personnel

parachute and survival kit in accordance with the

applicable maintenance manual.

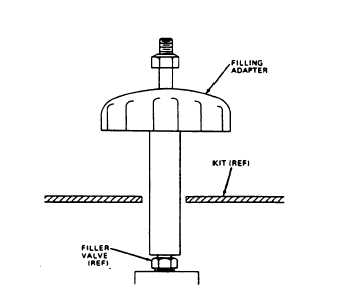

2. Remove the oxygen filler valve cap and

connect a filling adapter to the filler valve

(fig. 7-9). If the emergency oxygen system is

Figure 7-9.—Filling adapter.

7-8