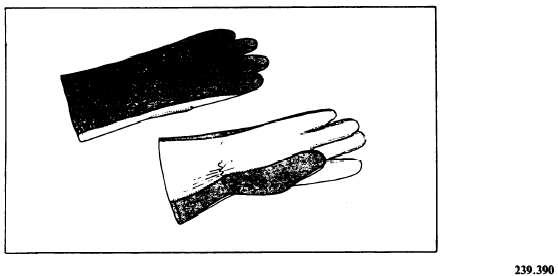

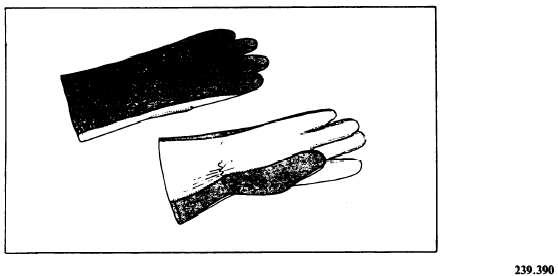

Figure 4-2.—Fire-resistant flyer’s gloves, GS/FRP-2.

of hand). The cloth portion of the gloves will not

melt or drip, and it does not support combustion.

The fabric does begin to char at 700° to 800°F.

Fitting

The fire-resistant flyer’s glove normally

corresponds to the aircrew member’s glove size.

Determine the proper size glove on a trial fit basis.

The glove must fit snugly.

Maintenance

It is the aircrew member’s responsibility to

clean the gloves. Repairs or other maintenance

actions are performed at the organizational level

or above, and are limited to restitching seams. The

gloves are laundered as follows:

1. Put on the gloves and wash with a mild

soap in water not over 120°F as if washing hands.

When the gloves are clean, rinse and remove them

from your hands. Squeeze, but do not wring the

gloves to remove excess water. Never use a

bleaching compound.

2. After removing excess water, place the

gloves flat on a towel and roll the towel to cover

the gloves. Ensure that the gloves do not contact

each other and are not exposed to hot air or

sunlight.

3. Letting the gloves come in contact with

each other may harm the soft leather palms. The

exposure to hot air or sunlight could cause the

gloves to shrink.

Figure 4-2.—Flyer’s boot.

FLYER’S BOOT

The impact-resistant flyer’s boot (fig. 4-3) is

designed to protect the aircrew member’s foot

against high-impact forces. The boot is water-

resistant.

Configuration

The upper boot is black in color and is

constructed of high quality calfskin. The inner

liner is made with soft, full grain, glove leather.

The boot is 8 inches high when fully laced, and

is available in sizes 4 narrow through 14 1/2 extra

wide. The traction tread outsoles and heels are

4-5